In any modern car there is a wiper, in which the drive of the brushes is carried out by a simple mechanism - a trapezoid. Read all about wiper trapezoids, their existing types, design and principle of operation, as well as the correct choice and replacement of these components in this article.

What is a wiper trapezoid?

Wiper trapezoid is a wiper drive, a system of rods and levers that provides reciprocating movements of the wiper blades on the windshield or rear door glass of vehicles.

On cars, buses, tractors and other equipment, there is always a wiper - an auxiliary system that cleans the windshield from water and dirt. Modern systems are electrically driven, and the transfer of force from the electric motor to the brushes is carried out using a system of rods and levers laid under glass - the wiper trapezoid.

The wiper trapezoid has several functions:

● Drive wiper blades from an electric motor;

● Formation of reciprocating motion of brushes (or brushes) with the required amplitude;

● In two- and three-blade wipers, it ensures synchronous movement of the blades along the same or different trajectories for each blade.

It is the wiper trapezoid that ensures the movement of the "wipers" on the glass with the required amplitude (scope) and synchrony, and the malfunction of this unit partially or completely disrupts the operation of the entire system. About the breakdown, the trapezoid must be repaired or replaced in the assembly, but before starting to repair, you should understand the existing types of these mechanisms, their design and principle of operation.

All vehicles, tractors and various machines are equipped with relay-regulators. The malfunction of this unit disrupts the operation of the entire electrical system, in some cases this can lead to breakdown of electrical equipment and fires. Therefore, a faulty regulator must be replaced as soon as possible, and for the correct choice of a new part, it is necessary to understand the existing types, design and principle of operation of regulators.

Types, design and principle of operation of the wiper trapezoid

First of all, all trapezoids can be divided into three types according to the number of brushes:

● For single-brush windshield wipers;

● For double-blade wipers;

● For three-blade wipers.

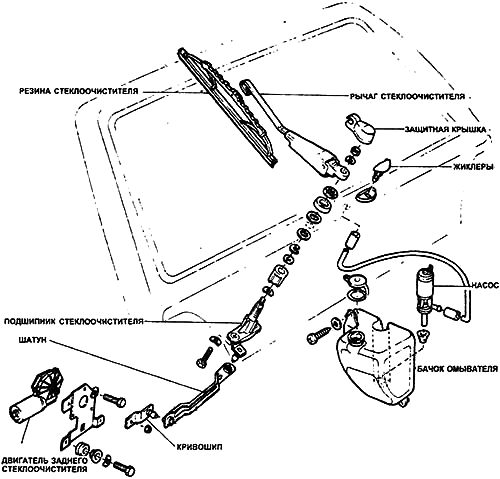

Diagram of a single-brush wiper

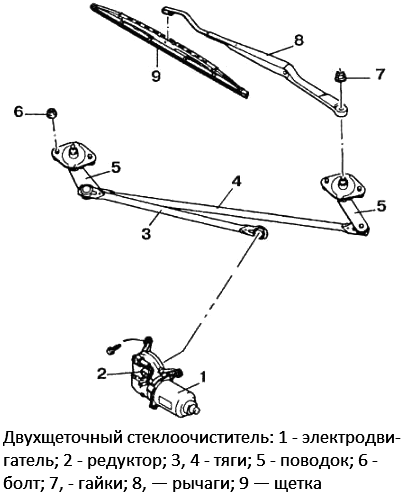

Diagram of a two-blade wiper

At the same time, the drive of one brush cannot be called a trapezoid, since in most cases it is built only on an electric motor with a gearbox without additional rods or with one rod. And two- and three-brush trapezoids have a fundamentally identical device and differ only in the number of rods.

In turn, two- and three-brush trapezoids can be divided into two types according to the place where the electric motor is connected:

● Symmetrical - the electric motor is located in the center of the trapezoid (between the brushes), ensuring the movement of both brush rods at once;

● Asymmetric (asymmetrical) - the electric motor is placed behind the trapezoid, providing its drive with additional lateral thrust.

Symmetrical wiper trapezoid

Asymmetrical wiper trapezoid

Today, asymmetric trapezoids are most common, they have a fairly simple device. In general, the basis of the design is made up of two hinged rods, in the hinge between the rods and at the end of one of them there are leashes - levers of small length, rigidly connected to the rollers of the brush levers. Moreover, the middle leash can be installed directly into the hinge joint of two rods (in this case, two rods and a leash come out of one point), or connect the rods with two hinges, and carry a roller in the middle part. In both cases, the leashes are perpendicular to the rods, which ensures their deflection during the reciprocating movement of the rods.

The rollers are made in the form of short steel rods, on the top of which threads are cut or slots are provided for a rigid fit of the wiper blade levers. Usually, the rollers are located in plain bearings, which, in turn, are held by brackets with holes for fasteners. With the free end of the second thrust, the trapezoid is attached to the gearbox of the electric motor, which has the simplest design - in the form of a crank directly located on the motor shaft, or mounted on the gear of a reduction worm gear. The electric motor and gearbox are assembled into a single unit, in which a limit switch can also be located, which ensures that the brushes stop in a certain position when the wiper is turned off.

Rods, leashes, rollers and brackets of the mechanism are made by stamping from sheet steel or by bending tubular blanks, which have high bending rigidity. Hinges are made on the basis of rivets or caps, plastic bushings and protective caps are installed in places of hinge joints, additional lubrication may also be provided. The hinge holes in the leashes are often oval to ensure the necessary trajectory of the brushes.

The wiper drive works as follows. When the wiper is turned on, the crank converts the rotational motion of the motor shaft into the reciprocating motion of the trapezoid rods, they deviate from their average position to the right and left, and through the leashes force the rollers to rotate at a certain angle - all this leads to characteristic vibrations of the levers and the brushes located on them.

Similarly, the trapezoids of three-brush wipers are arranged, they only add a third rod with a leash, the operation of such a system is no different from the one just described.

Symmetrical trapezoids are also a system of two articulated rods and leashes, but the leashes are located at opposite ends of the rods, and an additional leash or lever is installed in the hinge between the rods to connect to the gearbox of the electric motor. To increase rigidity and simplify installation, a bracket can be inserted into such a trapezoid - a pipe connecting the brush leashes, in the central part of which there can be a platform for mounting an electric motor with a gearbox. Such a system does not require separate fastening of leashes or rollers, which increases its convenience and reliability compared to other types of trapezoids.

Wiper trapezoids can be located under or above the windshield in a special niche (compartment) formed by body parts. Brackets with brush lever rollers are mounted on the body (flush) by means of two or three screws (or bolts), and the roller leads are usually sealed with rubber rings or protective caps / covers. The electric motor with a gearbox is mounted directly on the body part or on the bracket that comes with the trapezoid. Similarly, single-brush windshield wipers for the rear door glass are installed.

How to choose and replace the wiper trapezoid

During the operation of the wiper, the parts of its trapezoid wear out, deform or collapse - as a result, the entire mechanism ceases to perform its functions normally. A malfunction of the trapezoid is indicated by the difficult movement of the brushes, their periodic stops and desynchronization of movement, and all this may be accompanied by increased noise. To identify a malfunction, it is necessary to check the trapezoid, and if the breakdown cannot be eliminated, replace the mechanism.

Trapezoid three-blade wiper

Only those trapezoids that are designed specifically for this car should be taken for replacement - this is the only way to ensure that the wiper can be installed normally and it will work reliably. In some cases, it is permissible to use analogues, however, even on cars of the same model of different years of manufacture, the mechanisms may differ in the fastening and design of individual parts (which is associated with a change in the body structure, glass location, etc.).

Replacement of the trapezoid must be carried out in accordance with the instructions for the repair of the vehicle. Usually, to dismantle the entire mechanism, it is enough to remove the brush levers, then unscrew the fasteners of the roller brackets or the common bracket, and remove the trapezoid assembly with the motor and gearbox. In some cars, the trapezoid and the electric motor are removed separately, and access to their fasteners is carried out from different sides of the niche under the windshield. The installation of the new mechanism is carried out in reverse order, and it may be necessary to lubricate some parts. When performing installation, it is necessary to monitor the correct location of rods, leashes and other parts of the trapezoid, otherwise the operation of the mechanism may be disrupted. If the trapezoid has been selected and installed correctly, the wiper will work reliably, maintaining the cleanliness and transparency of the glass in all conditions.

Post time: Jul-14-2023