In any car, you can find a system for removing dirt from the windshield (and sometimes the rear) window - a windshield washer. The basis of this system is an electric motor connected to the pump. Learn about washer motors, their types, design and operation, as well as their purchase and replacement - find out from the article.

What is a washer motor

The washer motor is a compact DC electric motor that acts as a drive for an automobile windshield washer pump.

Every modern car has a system for cleaning the windshield (and on many cars - and the glass of the tailgate) from dirt - a windshield washer. The basis of this system is a pump driven by a washer motor - with the help of these units, liquid is supplied to the nozzles (nozzles) under a pressure sufficient to confidently clean the glass from dirt.

Breakdown of the windshield washer motor in many situations can disrupt the normal operation of the car, and sometimes lead to accidents. Therefore, this part should be replaced at the first sign of a malfunction, and in order to make the right choice, you should consider the features and characteristics of modern windshield washer motors.

Types, design and principle of operation of windshield washer motors

Modern windshield washers are equipped with 12 and 24 V DC electric motors (depending on the voltage of the on-board network), which differ in design:

● Separate electric motor and pump;

● Motor pumps are motors that are integrated into the pump housing.

The first group includes conventional low-power electric motors used in conjunction with submersible pumps. Currently, such a solution is almost never found on passenger cars, but it is still widely used in automotive equipment (especially domestic). An electric motor of this type is placed in a sealed plastic case that protects against water and dirt. With the help of a bracket or holes made in the housing, it is mounted on the reservoir with washer fluid, connecting to the pump located inside the tank using a shaft. Terminals must be provided on the motor body for connecting to the car's electrical network.

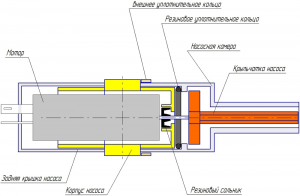

The second group includes units that combine a centrifugal pump and an electric motor. The design is based on a plastic case divided into two compartments with nozzles and auxiliary holes. In one compartment there is a pump: it is based on a plastic impeller that takes liquid from the supply pipe (located at the end of the pump, at the axis of the impeller), and throws it to the periphery of the body (due to centrifugal forces) - from here the liquid under pressure through the outlet pipe goes into the pipeline fittings and to the nozzles. To drain the liquid, a pipe is provided on the side wall of the pump compartment - it has a smaller cross-section than the inlet one, and is located tangentially to the circumference of the pump housing. In the second compartment of the unit there is an electric motor, the pump impeller is tightly mounted on its shaft (passed through the partition between the compartments). To prevent liquid from entering the compartment with the electric motor, a shaft seal is provided. An electrical connector is located on the outer wall of the unit.

Washer pump unit with remote motor and

submersible pump Motor-pump

with integrated electric motor

As in the case of a separate engine, the motor pumps are mounted directly on the windshield washer reservoir. To do this, special niches located at the bottom are made in the tank - this ensures the fullest use of the washer fluid. Installation is carried out without the use of screws or other fasteners - for this purpose clamping brackets or latches are used. Moreover, the inlet pipe of the pump is immediately installed in the hole in the tank with a rubber seal, which makes the use of additional pipelines unnecessary.

In turn, motor pumps are divided into three types according to performance and features of work:

● To supply fluid to only one washer nozzle;

● To supply fluid to two unidirectional jets;

● To supply fluid to two bidirectional jets.

Units of the first type have a pump of low capacity, sufficient only to power one washer nozzle. Two or three (if the rear window cleaning function is available) are installed in the windshield washer tank, each connected to the electrical system using its own connector. Such a solution requires the use of a larger number of parts, however, if one motor fails, the ability to partially wash the glass in case of contamination remains.

Units of the second type are similar in design to those just described, but they have higher performance due to the use of an electric motor of increased power and an increase in the pump. The motor-pump can be connected to the washer valve with two separate pipes leading to each nozzle, or with the help of one pipe with further branching of the pipeline into two streams (using a tee in the pipeline valves).

Units of the third type are more complicated, they have a different algorithm of operation. The basis of the motor-pump is also a body divided into two compartments, but in the pump compartment there are two pipes, between which there is a valve - only one of the pipes can always be opened at one time. The motor of this device can rotate in both directions - when changing the direction of rotation under the pressure of the liquid, the valve is triggered, opening one pipe, then the other. Typically, such motor pumps are used to wash the windshield and rear window: in one direction of rotation of the engine, the liquid is supplied to the nozzles of the windshield, in the other direction of rotation - to the nozzle of the rear window. For convenience, motor pump manufacturers paint the pipes in two colors: black - to supply fluid to the windshield, white - to supply fluid to the rear window. Bi-directional devices reduce the number of motor-pumps on the car to one - this reduces costs and simplifies the design. However, in the event of a malfunction, the driver is completely deprived of the opportunity to clean the windows of the car.

To connect motors and motor pumps, standard male terminals of various types are used: separate spaced terminals (two terminals to which two separate female terminals are connected), with a T-shaped arrangement (to protect against incorrect connection) and various two-terminal connectors in housings with protective plastic skirts and keys to protect against erroneous connection.

How to choose and replace the washer motor correctly

It has already been pointed out above that the windshield washer is important for the normal operation of the vehicle, so its repair, even with minor breakdowns, cannot be postponed. This is especially true for the motor - if it is out of order, it should be inspected and tried to be repaired, and if this is not possible, then replace it with a new one. For replacement, you should use a motor or motor-pump of the same type and model that was installed earlier - this is the only way to guarantee that the windshield washer will function reliably and efficiently. If the car is no longer under warranty, then you can try to choose a different type of unit, the main thing is that it has the necessary installation dimensions and performance.

The general structure of the washer motor pump

Replacement of parts should be carried out in accordance with the instructions for repairing the car. As a rule, this work is simple, it comes down to several operations:

1.Remove the wire from the battery terminal;

2.Remove the connector from the washer motor and pipe fittings from the pump pipe(s);

3.Dismantle the motor or motor pump assembly - for this you may need to remove the cover with the submersible pump (on old domestic cars), or remove the bracket or carefully remove the unit from its niche in the tank;

4.If necessary, clean the seat of the motor or motor pump;

5.Install a new device and assemble in reverse order.

If the work is carried out on a car with motor pumps, then it is recommended to put a container under the tank, since liquid may spill from the tank when dismantling the motor. And if the bidirectional motor-pump is being replaced, it is necessary to monitor the correct connection of pipelines to the pump pipes. After installation, you need to check the operation of the windshield washer, and, if a mistake is made, swap the pipelines.

With the correct selection and replacement of the washer motor, the entire system will start working without additional settings, ensuring the cleanliness of the windows in all weather conditions.

Post time: Jul-12-2023