In the front axle of all-wheel drive UAZ cars there are pivot assemblies with CV joints, which make it possible to transfer torque to the wheels even when they are turned. Kingpins play an important role in this unit - read all about these parts, their purpose, types, design and operation in this article.

What is a UAZ kingpin, its purpose and functions

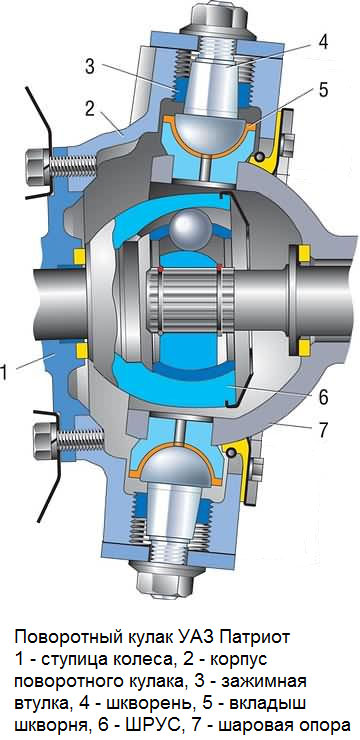

The kingpin is a rod that forms the hinge joint of the steering knuckle (assembled with the wheel hub) and the ball joint of the steering knuckle (SHOPK, inside the support there is a hinge of equal angular velocities, CV joint) on the front axle of all-wheel drive UAZ vehicles. Kingpins are components of a pivot mechanism that provides the ability to deflect the steered wheels without breaking the torque flow.

UAZ kingpins have the following functions:

• Act as axes around which the steering knuckle can swing;

• Act as connecting components that combine the ball joint and the steering knuckle into a single unit;

• Act as load-bearing components that provide the necessary rigidity of the pivot assembly, and also perceive the moments of forces arising during the movement of the car from the steering knuckle (and he, in turn, from the wheel) and transmit them to the axle beam.

UAZ kingpins, despite their simple design, play an important role in the functioning of the front axle of the SUV, and hence the entire car.

Types of UAZ kingpins

In general, the kingpin is a short rod of one shape or another, which is pressed into the body of the steering knuckle with the upper part, and the lower end has a hinge connection with the body of the ball joint. To connect the steering knuckle with the SHOPK, two kingpins are used - upper and lower, four kingpins are installed on the entire bridge, respectively.

Over the years, three main types of kingpins were installed on the front axles of UAZ cars:

• T-shaped cylindrical kingpins (with rotation in a bronze sleeve);

• Composite kingpins with a ball (with rotation on the ball);

• Composite bearing kingpins (with rotation on a tapered bearing);

• Cylindrical-conical kingpins with spherical support (with rotation in a bronze spherical liner).

T-shaped cylindrical kingpins are a classic solution that was installed on early models of UAZ cars with drive axles of the "Timken" type (with a detachable gearbox crankcase). Composite kingpins with a ball and a bearing are a more modern solution, these parts are placed on drive axles of the "Timken" type instead of conventional kingpins, they have the same dimensions. Kingpins with a spherical support began to be installed on new models of UAZ cars with drive axles of the "Spicer" type - UAZ-31519, 315195 ("Hunter"), 3160, 3163 ("Patriot") and their modifications.

Kingpins of various types have significant design differences.

Design and principle of operation of T-shaped cylindrical kingpins

Such a kingpin is a part in the form of two cylinders of different diameters, carved from a single workpiece. At the end of the upper (wide) part, in its center, a threaded channel is carved for installing an oiler. Nearby, with mixing from the center, a smaller diameter channel with smooth walls is drilled for the installation of a locking pin. On the side surface of the lower (narrow) part, an annular recess is provided for the distribution of lubricant. Also, a through longitudinal channel can be made in the pivot to lubricate the entire assembly assembly.

The kingpin is pressed into the body of the steering knuckle with a wide part and fixed with a steel lining (it is held by four bolts), and turning is prevented by a pin. With its narrow part, the kingpin is installed in a bronze sleeve pressed into the ball joint body. The sleeve is calibrated in such a way that the kingpin can rotate in it without jamming. Metal gaskets are laid between the wide part of the kingpin and the body of the ball joint, with the help of which the alignment of the entire pivot mechanism is carried out. To facilitate rotation and reduce the intensity of wear of parts, the kingpins are installed at a slight angle.

The mechanism works with these kingpins simply: when performing a maneuver, the steering knuckle deviates from the middle position by means of a bipod, the kingpins rotate with their narrow parts in bushings pressed into the ball joint body. When turning, grease from the kingpin channel enters the recess in its lower part, where it is distributed in the space between the kingpin and the sleeve - this reduces frictional forces and reduces the intensity of wear of parts.

The design and operation of kingpins on the ball

Such a kingpin consists of three parts: the upper one, pressed into the body of the steering knuckle, the lower one, pressed into the body of the SHOP, and a steel ball sandwiched between them. The ball is placed in hemispherical holes, carved in the end parts of the kingpin halves. To lubricate the ball, axial channels are made in the halves of the kingpin, and a threaded channel for the grease fitting is provided in the upper part of the kingpin.

The installation of kingpins on balls differs from the installation of a conventional kingpin only in that the lower half is rigidly installed in the body of the ball joint, so there is no bronze sleeve.

The pivot mechanism works with parts of this type simply: when the wheel is deflected, the upper part of the kingpin rotates on the ball, and the ball itself rotates somewhat relative to the halves of the kingpin. This ensures a reduction in frictional forces and a reduction in the intensity of wear of parts relative to a standard kingpin.

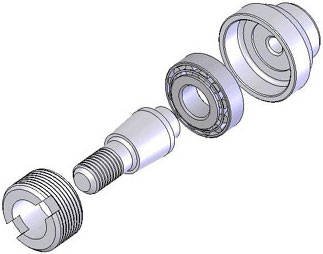

The design and principle of operation of the kingpins on the bearing

Structurally, the kingpin with a bearing is the most complex, it consists of three parts: the lower half, on which the tapered bearing is pressed (in addition, a thrust ring placed under the bearing can be used), and the bearing cage pressed into the steering knuckle housing. In the lower half there is an axial channel for supplying lubricant, in the bearing cage there is a side channel for the pin and a central channel for installing the grease fitter.

In essence, this type of kingpin is an upgrade of the kingpin on the ball, but here the two halves rotate on the bearing, which can significantly reduce friction forces and generally increase the reliability of the unit. The use of tapered bearings provides increased resistance to axial loads that occur during the operation of the vehicle.

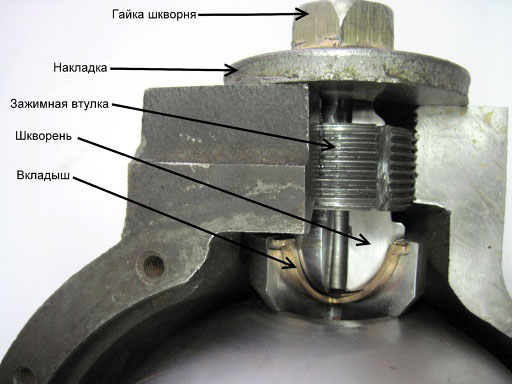

Design and principle of operation of kingpins with spherical support UAZ "Hunter" and "Patriot"

These kingpins combine the advantages of conventional kingpins and kingpins on a ball, from the first they took simplicity of design, from the second - improved performance and reduced friction forces. Structurally, the kingpin is a cylindrical-conical rod with a hemispherical head, carved from a single workpiece. On the narrow part of the kingpin, a thread for the nut is provided, a channel for lubrication is drilled along the axis of the part, and grooves are made on the head for distributing lubricant over rubbing surfaces.

The kingpin is rigidly installed in the body of the steering knuckle, a clamping sleeve is used for fixation, into which the kingpin enters with its conical part, and from above through a steel lining, the kingpin with the sleeve is tightened with a nut. The spherical part of the kingpin rests on a bronze liner (today there are modifications with plastic liners, but they are less reliable), which, in turn, is laid in the kingpin support on the SHOPK body. Adjustment of the relative position of the parts of the unit is carried out using gaskets placed under the kingpin lining.

The kingpin of this type works as follows: when the wheels are turned, the kingpins, rigidly connected to the body of the fist, rotate in the liners with their spherical heads. Moreover, such kingpins better perceive the deviations of the fist in the vertical plane, which ensures their long service life and reliability in any conditions.

Kingpins of all types wear out over time, for some time this wear can be compensated for by tightening parts or increasing the number of gaskets, but this resource is quickly exhausted and kingpins need to be changed. With the correct and timely replacement of kingpins, the car regains stability on the road and can be safely operated even in difficult conditions.

Post time: Aug-24-2023