All vehicles shall be equipped with intermittent direction indicator lights. The correct operation of direction indicators is provided by special interrupter relays - read all about these devices, their types, design and operation, as well as about the selection and replacement, in this article.

What is a turn relay?

Turn relay (turn indicator interrupter relay, current breaker) is an electrical or electronic device designed to close and open the circuit of the vehicle's light direction indicators in order to generate an intermittent signal to warn of the vehicle performing certain maneuvers.

This device has four main functions:

• Formation of an intermittent signal of the direction indicator lights on one side of the car (on the right or left) when performing the corresponding maneuvers;

• Generation of an intermittent signal of all direction indicator lights when the alarm is activated;

• Formation of an intermittent signal of the corresponding control lamp on the dashboard;

• Generation of an intermittent sound signal informing the driver of the turn indicators turned on.

The interrupter relay consists of three electrical circuits: two turn signal light circuits on the right and left sides of the vehicle, and one alarm circuit (which includes direction indicators on both sides of the vehicle). To activate the light alarm, the relay is connected to the corresponding circuit using a paddle shifter. Therefore, usually only one turn relay is installed on vehicles.

The current rules of the road and standards establish that all motor vehicles operated on the territory of the Russian Federation must be equipped with direction indicators, and the use of this alarm is mandatory when performing any maneuvers. If the light alarm is not working, it is necessary to take measures to eliminate malfunctions, most often the repair is reduced to a simple replacement of the turn signal interrupter relay. But before buying and changing relays, you need to understand the types of these devices that exist today, their structure and characteristics.

Classification, device and principle of operation of the rotation relay

On cars, tractors and other equipment, two main types of relays are used:

• Electromagnetothermal;

• Electronic.

Devices of these types differ in the physical principles of operation laid down in them and, accordingly, the design.

Electromagnetothermal current breakers. These are turn relays of the old design, which have been used on cars for several decades, but thanks to a simple device and reliability, they still have not lost their relevance.

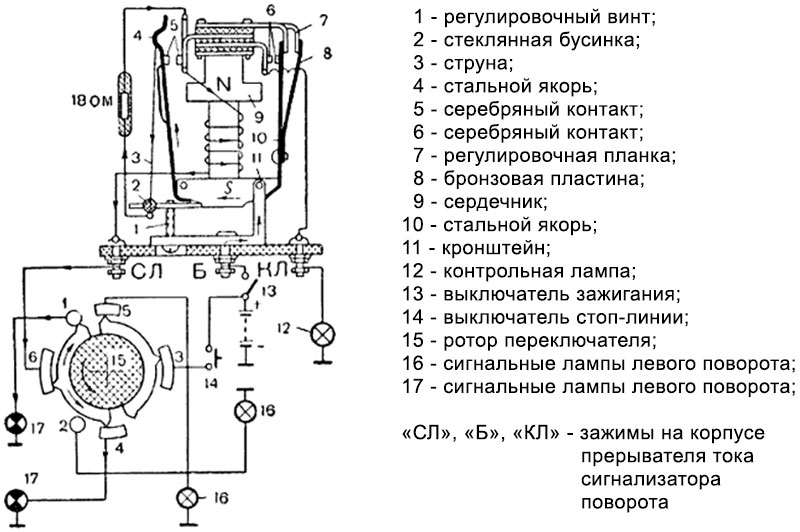

The basis of this device is an electromagnetic core with a coil and two steel anchors with contact groups. One anchor is pulled away from its contact by a thin string of nichrome (a metal with high resistivity and a high coefficient of thermal expansion), the second anchor is held at some distance from its contact by a springy bronze plate. This type of relay functions quite simply. When the direction indicators are turned on, the current passes through the core winding, the nichrome string and the resistor, the resistance of this circuit is high, so the lamps glow half-glow. Within a short time, the string heats up and lengthens due to thermal expansion - the armature is attracted to its contact and closes the circuit - in this case, the current flows around the string and the resistor, the direction indicator lamps glow with full incandescence. The de-energized string is quickly cooled, shortened and pulls the armature from contact - the circuit is broken, the current flows through the string again and the process repeats.

At the moment of closing the contacts, a large current flows through the electromagnetic core, a magnetic field is formed around it, which attracts the second armature - the second group of contacts closes, which turns on the lamp on the dashboard. Due to this, the operation of the direction indicators is duplicated by the intermittent operation of the lamp on the dashboard. The described processes can occur with a frequency of 60-120 times per minute (that is, each cycle of heating and cooling the string takes from 0.5 to 1 second).

The design of the electromagnetothermal relay

Electromagnetothermal relays are usually placed in a cylindrical metal case with screw or knife contacts, they can be mounted in the engine compartment or under the dashboard.

Electronic turn breakers. These are modern devices that are used on all new cars. Today, there are two types of electronic relays:

• With electromagnetic relay for connecting the load (turn signal lamps);

• With electronic key to connect the load.

In the first case, the turn relay consists of two functional blocks - a simple electromagnetic relay and an electronic key on a semiconductor device (on a transistor or microcircuit). The electronic key acts as a clock generator, which, with a predetermined frequency, supplies current to the winding of the electromagnetic relay, and the relay contacts, closing and opening, ensure that the direction indicators are turned on and off.

In the second case, instead of an electromagnetic relay, an electronic key on a high-power transistor is used, which provides connection and disconnection of direction indicators with the required frequency.

Electronic relays are usually placed in standard plastic cases with knife contacts, they are usually installed in the relay and fuse box, less often under the dashboard or in the engine compartment.

Questions of the correct purchase and replacement of the turn relay

A malfunctioning relay is one of the common problems of the electrical system of cars, and although the rules of the road do not prohibit the operation of a vehicle with faulty turn indicators (since signals can be given by hand), this part should be replaced as soon as possible in the event of a breakdown. To replace, you need to choose a relay of the same type and model that was installed on the car earlier. However, today there are many analogues of the most common turning relays on the market, and among them you can choose the right device. For the right choice, you need to consider the following:

• Supply voltage - the relay must correspond to the power supply of the vehicle's electrical network (12 or 24 volts);

• The number and location of contacts (pinout) - the relay must fall into place in the relay and fuse box or in a separate connector without any modifications;

• Dimensions of the case - the relay should not go beyond the dimensions of the relay box and fuses (although there are exceptions here).

Modern relays are easy to change - you need to open the relay and fuse box, remove the old relay, if necessary, clean the electrical connector (remove dirt and dust), and insert a new relay. Electromagnetothermal breakers with screw connectors require more manipulations: you need to loosen the nuts of the old relay, remove the wires and fix them on the new relay. In this case, the relay itself is usually mounted on the body using a bracket and a bolt. In some cases, electromagnetothermal relays allow a change in the frequency of current interruption - for this, the device must be disassembled and adjusted by turning the screw that pulls the nichrome string.

With the right selection and installation, the relay will start working immediately, ensuring compliance with traffic rules.

Post time: Aug-18-2023