Trailers and semi-trailers are equipped with an air brake system that works in concert with the brakes of the tractor. The coordination of the functioning of the systems is ensured by the air distributor installed on the trailer / semi-trailer. Read all about this unit, its types, design and operation in the article.

What is a trailer/semi-trailer brake diffuser?

The air distributor of the brakes of a trailer / semi-trailer (air distribution valve) is a control and control component of the brake system of trailers and semi-trailers with a pneumatic drive. A unit with a system of ducts and valves that ensures the distribution of compressed air flows between the components of the system.

The air distributor is designed to control a road train and a separate trailer / semi-trailer:

• Braking and braking of a trailer / semi-trailer as part of a road train;

• Braking of the trailer / semi-trailer when disconnected from the car;

• Unfastening of the trailer / semi-trailer if necessary, maneuvers without attaching to the tractor;

• Emergency braking of the trailer / semi-trailer when separating from the road train.

All cargo trailers and semi-trailers are equipped with brake air distributors, but they differ in purpose, type and design, which needs to be described in more detail.

Types and applicability of brake diffusers

Air distributors are divided into groups according to the type of pneumatic actuator of the brake system in which they can operate, and the configuration.

There are three types of air diffusers:

• For single-wire braking systems;

• For two-wire braking systems;

•Universal.

Single-wire brakes of trailers and semi-trailers are connected to the pneumatic system of the car with one hose. With its help, both the filling of the receivers of the trailer / semi-trailer and the control of its brakes are carried out. Two-wire braking systems are connected to the pneumatic system of the tractor by two lines - feeding, through which the trailer receivers are filled, and control.

To work in a single-wire brake system, air distributors with a tracking mechanism are used, which monitors the pressure in the line and, depending on it, supplies compressed air from the trailer receiver to its brake chambers.

To work in a two-wire system, air distributors with a separate tracking mechanism are used, which monitors the pressure in the control line, and, depending on it, controls the air supply from the receivers to the components of the brake system of the trailer / semi-trailer. Universal air diffusers can operate in both one- and two-wire braking systems.

In terms of configuration, there are two types of air distributors:

• Without additional equipment;

• With built-in release valve (KR).

In the first case, the air distributor includes only components that provide automatic distribution of compressed air throughout the system, depending on the pressure in the pneumatic system of the tractor (or in the control line). For the release and braking of a trailer/semi-trailer disconnected from the road train, a separate manually operated release valve is used, which can be installed next to the air distributor or on its body. In the second case, the air distributor has a built-in release valve.

Design and principle of operation of brake diffusers

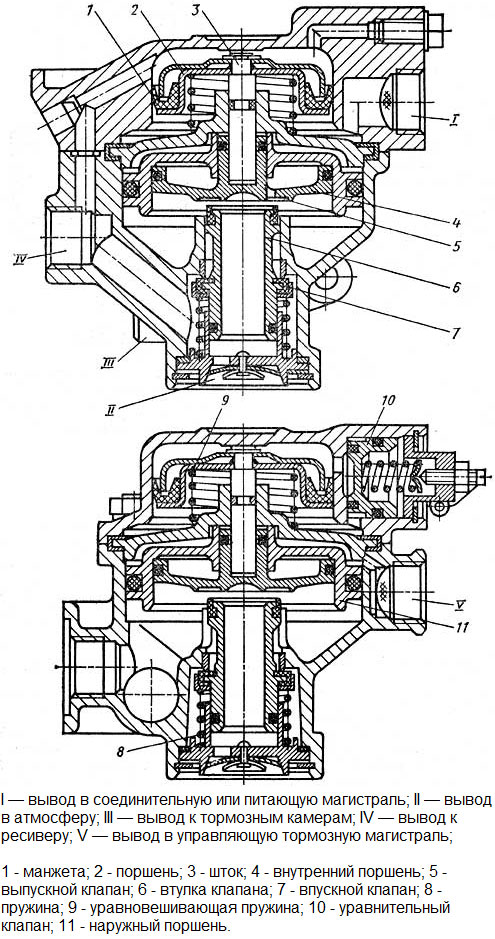

Today, a large number of models of air distribution valves of trailers and semi-trailers are produced, but they all have a fundamentally identical device. The unit combines several pistons and valves that switch the line from the tractor, receiver and wheel brake chambers, depending on the condition of the tractor's brake system. Let's consider the design and principle of operation of the universal (used in both single- and 2-wire brake systems) air distributor of KAMAZ trailers with a separate release valve.

Just note that the air distributor controls the brake system of the trailer only when using the main brake system of the tractor. If a spare or parking brake system is used on the tractor, the air supply to the components of the trailer brake system is controlled by a solenoid valve. We will not consider the work of this node here.

The operation of the air distributor in a single-wire circuit of the pneumatic system

The device of a universal air distributor

The line from the pneumatic system of the tractor is connected to the pipe I; Nozzle II remains free and connects the system to the atmosphere; pipe III is connected to the brake chambers; Pin IV - with the trailer receiver. With this connection, the V pipe remains free.

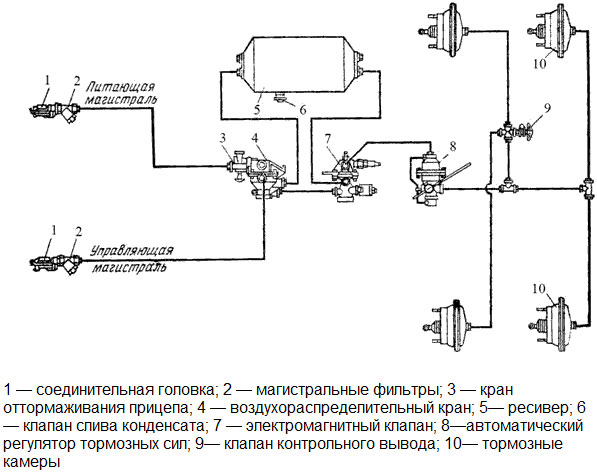

Diagram of a single-wire pneumatic system

The line from the pneumatic system of the tractor is connected to the pipe I; Nozzle II remains free and connects the system to the atmosphere; pipe III is connected to the brake chambers; Pin IV - with the trailer receiver. With this connection, the V pipe remains free.

Connection of the trailer with the tractor. The movement of the road train. In this mode, compressed air from the car line through the pipe I enters the piston chamber 2, passes through the cuff skirt 1 and freely penetrates into the piston chamber, through the channel enters the pipe IV and from it to the receivers. The exhaust valve 5 remains open, so the brake chambers communicate with the atmosphere through the pipe III, valve 5, its sleeve 6 and pipe II. Thus, while driving as part of a road train, the receivers of the trailer / semi-trailer are filled, and the brakes do not work.

Braking of the road train. At the moment of braking of the tractor, the pressure in the line and on the pipe I decreases. At some point, the pressure from the side of the pipe IV (from the receivers of the trailer / semi-trailer) exceeds the pressure from the side of the pipe I, the edges of the cuff are pressed against the cavity body and the piston, overcoming the elasticity of the spring 9, moves down. Together with the piston 2, the rod 3 and the lower piston 4 associated with it move, the latter valve seat 5 is adjacent to the end face of the sleeve 6, it also moves down and opens the intake valve 7. As a result, compressed air from the receivers of the trailer / semi-trailer through the IV pipe enters the III pipe and to the brake chambers - the wheel brakes are triggered and braking occurs.

Disinbition of the road train. When the tractor is released, the pressure on the pipe I increases, as a result, the pipe I is again connected to the pipe IV (the trailer receivers are filled), and the brake chambers bleed the air through the pipes III and II - braking occurs.

Emergency braking in case of hose breakage, disconnection of the trailer / semi-trailer from the road train. In both cases, the pressure at the terminal II drops to atmospheric pressure and the air distributor works as in normal braking.

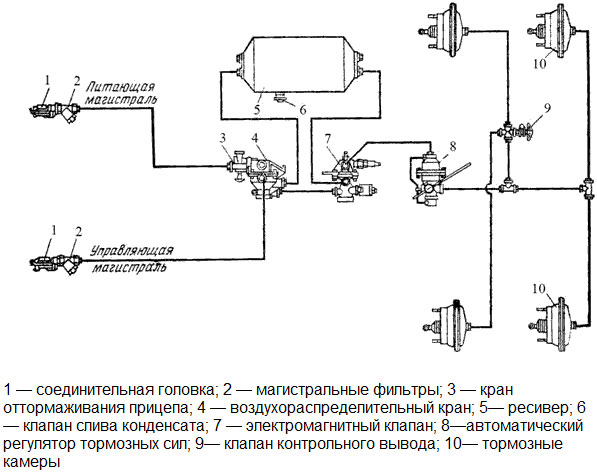

Operation of the air distributor with a two-wire scheme of the air distributor

Diagram of a two-wire pneumatic system

Two lines from the tractor are connected to the air distributor - supplying to the pipe I and controlling to the pipe V. The remaining pipes have a connection similar to a single-wire circuit. Also, with a 2-wire pneumatic actuator circuit, the equalizing valve 10 comes into operation. With this connection scheme, a higher pressure is applied to the pipe I than with a single-wire circuit, which makes it difficult to move the piston 2 and disrupts the operation of the entire braking system. This problem is eliminated by an equalizing valve - at high pressure, it opens and connects the cavities above and below the piston, equalizing the pressure in them.

Connection of the trailer / semi-trailer with the tractor. Movement of the road train. In this case, the air from the supply hose through the pipes I and IV fills the receivers, the remaining components of the air distributor do not work.

Braking of the road train. When the tractor is braked, the pressure rises on the V pipe, compressed air enters the chamber above the piston 11, causing it to move downwards. In this case, the processes described above occur - the valve 5 closes, the valve 7 opens, the pipes IV and III are connected, and the air from the receivers enters the brake chambers, braking.

Disinbition of the road train. When the tractor is released, all processes occur in reverse order: the pressure on the pipe V drops, the piston rises, the pipe III is connected to the pipe II, the air from the brake chambers is released and the trailer is released.

Emergency braking in case of a break in the line, disconnection of the trailer. In these cases, the role of the tracking mechanism is performed by the equalizing valve. When the pressure on the pipe II is reduced to atmospheric pressure, the valve closes, separating the chambers above and below the piston 2. As a result, the pressure above the piston (due to the air coming from the receivers through the IV pipe) increases, and processes similar to braking occur with a single-wire connection scheme. Thus, when the hose is broken/disconnected or when the road train is disbanded, the trailer/semi-trailer automatically brakes.

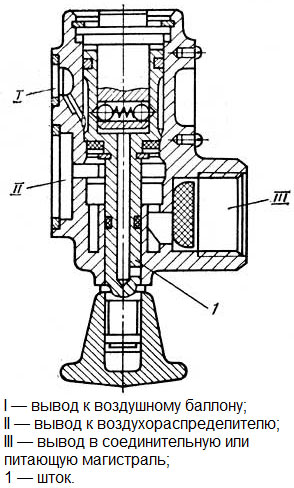

Design and principle of operation of the release valve

The CD has a simple structure and operation. Consider the functioning of this unit on the example of a crane trailers of the Kama Automobile Plant.

The unit can be installed directly on the body of the air distributor or located next to it in a more convenient place. Its nozzle I is connected to the receiver of the trailer / semi-trailer through the air distributor channel or by a separate pipeline. Nozzle II is connected to the guy I of the air distributor, and pipe III is connected to the main line of the car.

During the main time of operation of the trailer, the rod 1 is in the upper position (it is fixed in this position by means of spring-loaded balls that rest against the recesses in the body of the device), the air from the nozzle III enters the pipe II, and the terminal I remains closed, so the valve does not affect the operation of the air distributor.

If it is necessary to move the detached trailer, you need to move the rod 1 down with the help of the handle - this will lead to the separation of pipes II and III and the connection of pipes II and I. As a result, the air from the receiver is directed to the inlet I of the air distributor, the pressure on it rises and processes occur similar to the braking processes with a single-wire pneumatic drive circuit - the trailer is released. For braking, it is necessary to return the rod to the upper position.

The device of the release valve

Selection, replacement and maintenance of the brake diffuser

The brake air distributor is constantly subjected to high loads, gaps increase in its moving parts, which can cause air leaks, deterioration of performance or, conversely, spontaneous operation of the brakes. In case of any problems, it makes sense to replace the assembly assembly.

When choosing an air distributor, you should be guided by the recommendations of the trailer manufacturer, and install units of certain models and catalog numbers. However, today the market offers a wide range of original air distributors and their analogues with improved characteristics. Therefore, in some cases, it is justified to install an analogue, but in order to avoid problems in the future, it is necessary to choose analogues with suitable connecting dimensions and characteristics.

With the right choice and installation of the air distributor, the brakes of a trailer or semi-trailer will work reliably and efficiently in all conditions, ensuring the safety of the road train.

Post time: Aug-21-2023