In the engine preheaters there are sensors that monitor the temperature of the coolant and control the operation of the device. Read about what heater temperature sensors are, what types they are, how they are arranged and work, how to replace them - read in this article.

What is a PZD temperature sensor?

The PZD temperature sensor is an element of the control system of the engine preheater (liquid engine heater, PZD), a sensitive element (measuring transducer) for measuring the temperature of the coolant.

The data obtained using the temperature sensor are sent to the electronic control unit of the Railway, and on their basis the heater is automatically turned on, changing its operating modes, regular or emergency shutdown. The functions of the sensors depend on their type and place of installation in the railway.

Types, design and principle of operation of temperature sensors

Temperature sensors are divided into groups according to the principle of operation laid down in the basis of their work, the type of output signal, design and applicability.

According to the principle of operation, sensors are:

● Resistive - they are based on a thermistor (thermistor), the resistance of which depends on temperature. When the temperature changes, the resistance of the thermistor increases or decreases, this change is recorded and used to determine the current temperature;

● Semiconductor - they are based on semiconductor devices (diode, transistor or other), the characteristics of the "p-n" transitions of which depend on temperature. When the temperature changes, the current-voltage characteristic of the "p-n" junction (the dependence of the current on the voltage) changes, this change is used to determine the current temperature.

Resistive sensors are the simplest and cheapest, but for their operation it is necessary to use a separate measuring circuit, which requires calibration and adjustment. Semiconductor sensors make it possible to manufacture heat-sensitive microcircuits with an integrated measuring circuit that produces a digital signal at the output.

According to the type of output signal, there are two types of temperature sensors:

● With analog signal output;

● With digital signal output.

The most convenient sensors are those that generate a digital signal - it is less susceptible to distortion and errors, it is easier to process with modern digital circuits, and the digital signal makes it easy to adapt the sensor to measure different temperature intervals and to different operating modes.

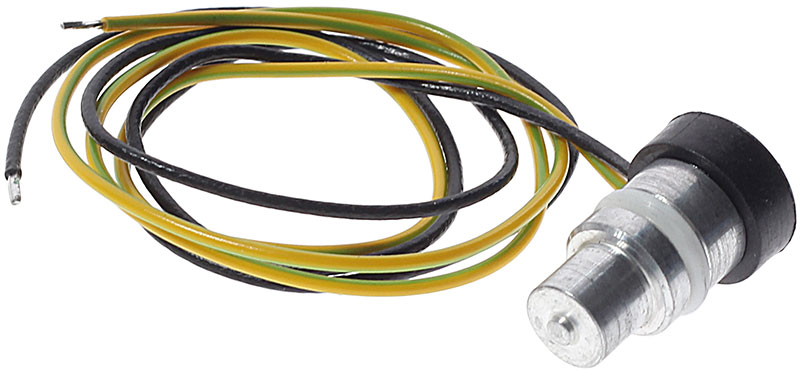

Modern railway sensors for the most part are built on the basis of temperature-sensitive microcircuits with a digital output signal. The basis of such a sensor is a cylindrical case made of corrosion-resistant metal (or with an anti-corrosion coating), inside of which a heat-sensitive microcircuit is mounted. On the back of the case is a standard electrical connector or a wiring harness comes out with the connector(s) at the end. The case is sealed, it protects the chip from water and other negative influences. On the outside of the case, there is a groove for the installation of a rubber or silicone O-ring, and an additional gasket can also be used. The resistive sensor is designed similarly, but it has a narrow elongated housing, at the end of which there is a sensitive element.

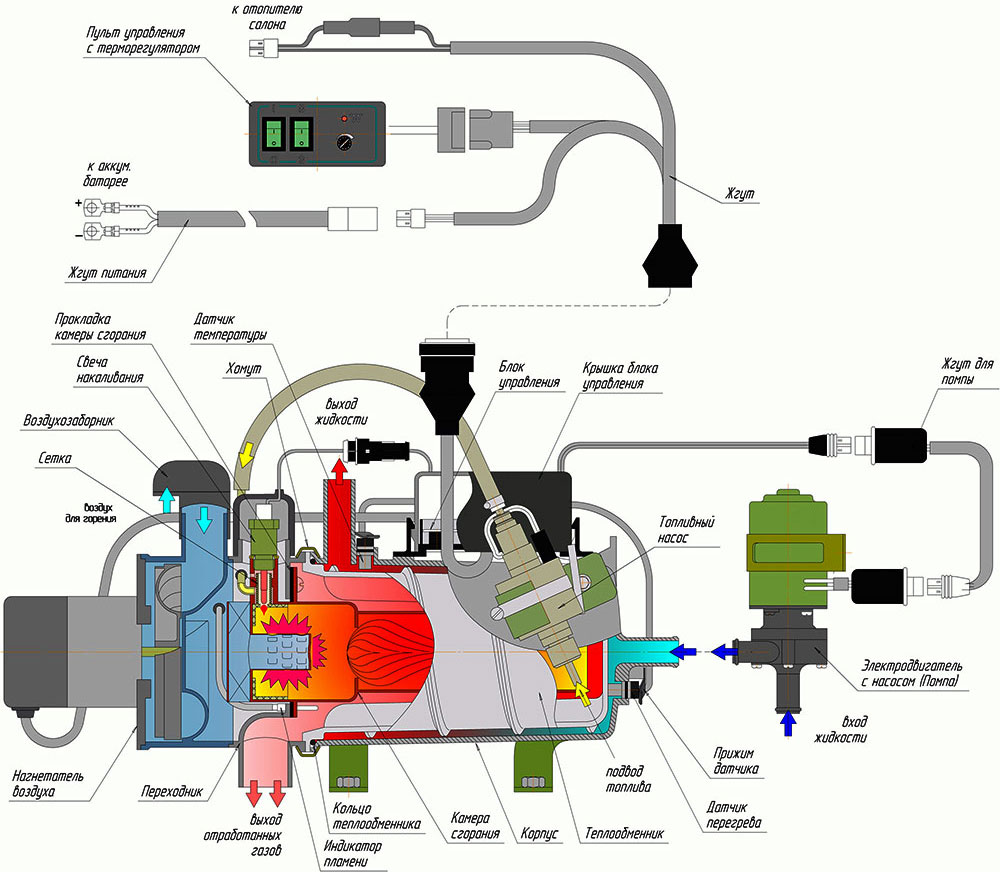

Scheme of the railway with an indication of the installation locations of temperature and overheating sensors

Regardless of the design, PZD temperature sensors are divided into three types according to their applicability:

● Temperature sensors - used to measure the temperature of the outgoing liquid that flows from the heater to the cooling system of the power unit;

● Overheating sensor - used to measure the temperature of the incoming liquid that enters the heater from the cooling system of the power unit;

● Universal - can work as a temperature sensor for outgoing and incoming liquid.

The temperature sensor of the outgoing liquid is installed on the side of the exhaust liquid pipe of the heater, it is used by the control system to turn the heater on and off when a certain engine temperature is reached (usually in the range from 40 to 80 ° C, depending on the selected program and operating mode of the railway). Since this sensor is used to monitor and control the heater, it is simply called a temperature sensor.

The overheating sensor is installed on the side of the preheater liquid inlet, it is used to automatically turn off the device when the coolant is overheated. If, for one reason or another, the control unit does not turn off the heater when the temperature reaches over 80 ° C, then the protective circuit is triggered, which forcibly turns off the preheater, preventing the engine from overheating.

Universal sensors can perform the functions of both devices, they are installed on the exhaust or inlet liquid pipe, and are configured in accordance with the functions assigned to them.

In modern preheaters, two sensors are used - temperature and overheating. Their signal is fed to the corresponding inputs of the railway control unit, while the signal from the temperature sensor (outgoing liquid) can be used to display information on the display of the control panel in the passenger compartment / cab of the car, and the signal from the overheating sensor can be used to notify of engine overheating.

Selection and replacement of temperature sensors

Modern heaters have self-diagnostic systems that notify the driver of a malfunction of temperature sensors with a signal on the display of the control panel or by flashing the LED. In all cases, if a malfunction is suspected, it is necessary to check the reliability of electrical connections and the sensor - how to do this is indicated in the instructions for operation and repair of the railway. If a malfunction is detected, the temperature sensor should be replaced, otherwise the heater cannot be operated normally.

For replacement, it is necessary to select sensors of those catalog numbers and types that are indicated in the instructions for the railway. Today, many manufacturers offer analogues of the most popular devices, which greatly facilitates their choice. However, when choosing, you cannot blindly trust the seller - you need to make sure that the new sensor has the appropriate type of connector and has a gasket in the kit.

Replacement of temperature and overheating sensors is carried out in accordance with the instructions for the railway, but regardless of the heater model, this work must be performed only on a stopped engine with the terminals removed from the battery and after draining the liquid from the cooling system. When installing a new sensor, it is necessary to observe the polarity of the connection of electrical contacts, and after filling in the coolant, air the system.

With the right choice and replacement of the temperature sensor, the engine heater will work reliably and correctly in all situations.

Post time: Aug-21-2023