In the steering gear of almost all wheeled vehicles, there are elements that transmit force from the steering mechanism to the wheels - steering rods. Everything about tie rods, their existing types, design and applicability, as well as the correct selection and replacement of these parts - read the proposed article.

What is tie rod?

Steering rod - an element of the drive of the steering mechanism of wheeled vehicles (with the exception of tractors and other equipment with a breaking frame); A part in the form of a rod with a ball joint (hinges), which ensures the transfer of force from the steering mechanism to the levers of the steering knuckles of the wheels and to other components of the steering drive.

The steering of wheeled vehicles is divided into two main parts: the steering mechanism and its drive. The steering mechanism is controlled by the steering wheel, with its help a force is created to deflect the steered wheels. This force is transmitted to the wheels by means of a drive, which is a system of rods and levers connected by hinges. One of the main parts of the drive are tie rods that are different in location, design and purpose.

The steering rods have several functions:

● Transmission of force from the steering mechanism to the associated components of the drive and directly to the levers of the steering knuckles of the wheels;

● Holding the selected angle of rotation of the wheels when performing maneuvers;

● Adjustment of the angle of rotation of the steered wheels depending on the position of the steering wheel and other adjustments of the steering gear in general.

The tie rods solve the important task of transferring forces from the steering mechanism to the steered wheels, therefore, in the event of a malfunction, these parts must be replaced as soon as possible. But for the right choice of a new thrust, it is necessary to understand the existing types, designs and features of these parts.

Types and applicability of tie rods

Tie rods can be divided into several types according to their purpose, applicability and some design features.

In terms of applicability, there are two types of traction:

● For steering systems based on worm and other steering mechanisms and with a drive in the form of a steering trapezoid;

● For steering systems based on steering racks with direct wheel drive.

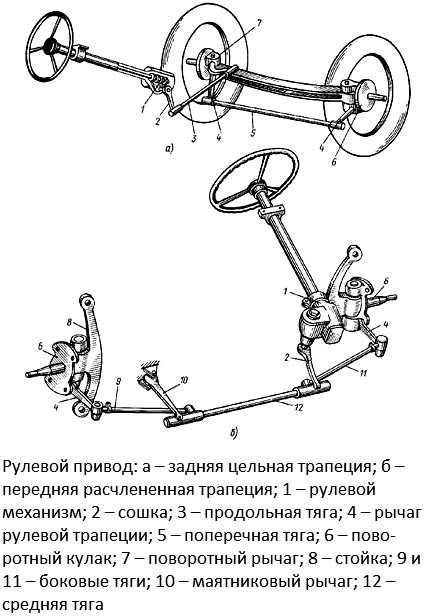

In systems of the first type (with steering trapezoids), two or three rods are used, depending on the type of suspension of the steered axle and the steering trapezoid scheme:

● On an axle with a dependent suspension: two rods - one longitudinal, coming from the steering bipod, and one transverse, connected to the levers of the steering knuckles of the wheels;

● On an axle with independent suspension: three rods - one longitudinal middle (central), connected to the bipod of the steering mechanism, and two longitudinal lateral, connected to the middle and to the levers of the steering knuckles of the wheels.

There are also options for trapezoids on the axle with independent suspension with two side rods connected to the steering bipod at the center point. However, the drive of such a scheme is more often used in steering based on steering racks, which are described below.

Types and schemes of trapezoid steering

It should be noted that in steering trapezoids for an axle with independent suspension, one tie rod is actually used, divided into three parts - it is called a dismembered rod. The use of a dismembered tie rod prevents spontaneous deflection of the steered wheels when driving on bumps in the road due to different amplitude of oscillation of the right and left wheels. The trapezoid itself can be located in front and behind the axle of the wheels, in the first case it is called the front, in the second - the rear (so do not think that the "rear steering trapezoid" is a steering gear located on the rear axle of the car).

In steering systems based on the steering rack, only two rods are used - right and left transverse to drive the right and left wheels, respectively. In fact, this is a steering trapezoid with a dissected longitudinal rod with a hinge at the midpoint - this solution greatly simplifies the design of the steering, increasing its reliability. The rods of this mechanism always have a composite design, their outer parts are usually called steering tips.

Tie rods can be divided into two groups according to the possibility of changing their length:

● Unregulated - one-piece rods that have a given length, they are used in drives with other adjustable rods or other parts;

● Adjustable - composite rods, which, due to certain parts, can change their length within certain limits to adjust the steering gear.

Finally, rods can be divided into many groups according to their applicability - for cars and trucks, for vehicles with and without power steering, etc.

Tie rod design

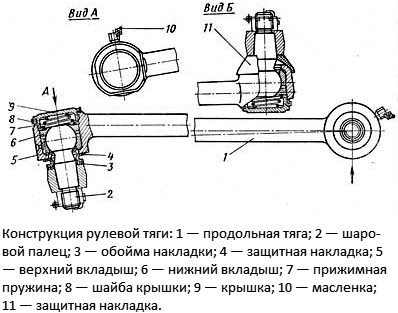

The simplest design has unregulated rods - they are based on a hollow or all-metal rod of a profile (can be straight or curved in accordance with the design features of the car), at one or both ends of which ball joints are located. The hinges are non-separable, consist of a body with a ball pin located inside with a thread for the crown nut and a transverse hole for the cotter pin; The hinge can be closed with a rubber boot to protect against dirt and water. On the transverse thrust, the axes of the fingers of the ball joints are located in the same plane or shifted at a small angle. On the longitudinal thrust, the axes of the hinge pins are usually perpendicular to each other.

Somewhat more complex design have unregulated transverse rods. In such a thrust, additional elements may be provided:

Radiator and expansion tank plug with combined valves located on the same axis

● In rods for axles with dependent suspension - a hole or hinge for connection to the steering bipod;

● In rods for axles with independent suspension - two symmetrically arranged holes or hinges for connection with side rods;

● In rods for cars with hydrostatic steering (GORU) - a bracket or hole for connecting to the rod of the hydraulic cylinder GORU.

However, trapezoids with a pendulum arm are widely used on many cars - in such systems, the middle transverse thrust at its tips has holes for mounting the pendulum lever and steering bipod.

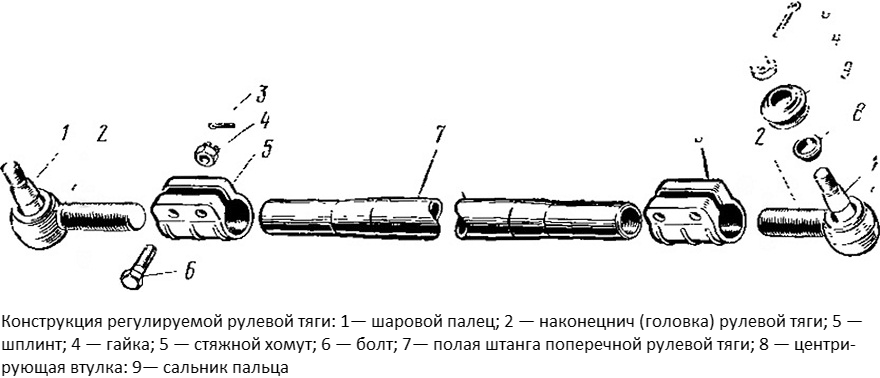

Adjustable tie rods consist of two main parts: the rod itself and the steering tip connected to it. The tip in one way or another can change its position relative to the thrust, which allows you to adjust the overall length of the part. According to the method of adjustment, the thrust can be divided into two types:

● Thread adjustment with locknut fixation;

● Adjustment by thread or telescopic method with fixation with a tie clamp.

In the first case, the tip has a thread that is screwed into the counter thread at the end of the rod, or vice versa, and the fixation from turning is carried out by a locknut on the same thread. In the second case, the tip can also be screwed into the rod, or simply inserted into it, and fixation from turning is carried out by a tightening clamp on the outer surface of the rod. The tightening clamp can be narrow and tightened with only one bolt with a nut, or wide with a tightening of two bolts.

Adjustable tie rod design with tie clamps

All tie rods are hinged to each other and to other parts of the steering system - this ensures the normal functioning of the system during deformations that occur while the vehicle is moving. The axes of the hinges are ball pins, they are fixed in the holes of the mating parts with crown nuts fixed with cotter pins.

Rods are made of steel of various grades, they can have a protective coating in the form of ordinary paint or electroplating with various metals - zinc, chromium and others.

How to choose and replace the tie rod

The steering rods are subjected to significant loads during the operation of the car, so they quickly become unusable. Most often, problems arise in ball joints, and rods are also subject to deformation and cracking, followed by the destruction of the part. A malfunction of the rods may be indicated by the backlash and beating of the steering wheel, or, on the contrary, an excessively tight steering wheel, various knocks while driving, as well as a loss of directional stability of the car (it leads to the side). When these signs appear, the steering should be diagnosed, and if problems with the rods are found, then they need to be replaced.

For replacement, you should choose those steering rods and tips that were installed on the car earlier - this is the only way to guarantee that the steering will function correctly. If the problem occurred only in one side rod or tip, then it is better to replace these parts in pairs, otherwise there is a very high probability of breakage of the rod on the second wheel.

Replacement of rods must be carried out in accordance with the instructions for repair and maintenance of the car. Usually, this operation comes down to lifting the car on a jack, dismantling old rods (for which it is better to use a special puller) and installing new ones. After repair, it is recommended to adjust the wheel alignment. New rods on some vehicles (especially trucks) should be lubricated periodically, but usually these parts do not require maintenance during their entire service life.

With the right choice and replacement of tie rods, driving will be reliable and confident in all driving modes.

Post time: Jul-26-2023