In recent decades, mechanical car speedometers have been replaced by electronic speed measurement systems, in which speed sensors play an important role. Everything about modern speed sensors, their types, design and operation, as well as their correct choice and replacement - read in this article.

What is a speed sensor

Speed sensor (vehicle speed sensor, DSA) is a sensitive element of the electronic vehicle speed measurement system; A contact or non-contact sensor that measures the angular velocity of the shaft in the gearbox or in the drive axle gearbox and transmits the measurement results to the vehicle's speed controller or speedometer.

Please note: the article discusses only DSA for measuring the speed of a car. About wheel speed sensors operating as part of active safety systems (ABS and others), described in other articles on our website.

Speed sensors can be part of various systems of a modern vehicle:

● Speedometer - to measure and indicate the current speed of movement and the distance traveled (using an odometer);

● Injection, ignition and other engine systems - to correct the operating modes of the power unit, depending on the speed of the car and its changes (during acceleration and braking);

● Active security and alarm systems – to correct the speed and trajectory of the car in various modes, warning of potentially dangerous situations, etc.;

● In some cars - power steering and comfort systems.

The DSA, like the traditional cable drive of the speedometer, is mounted on the gearbox, transfer case or drive axle gearbox, tracking the angular velocity of the secondary or intermediate shaft. The information received from the sensor in the form of electrical signals is sent to the speed controller or directly to the speedometer. The characteristics of the generated signals and the methods of connecting/integrating sensors with vehicle electronics depend on their types, design and principle of operation. This needs to be described in more detail.

Functionality, types, design and principle of operation of speed sensors

Speed sensors, regardless of type and design, generate signals that can be sent either directly to the speedometer or to the engine controller and associated electronic control units. In the first case, the sensor is used only to visually determine the speed of the vehicle. In the second case, the data is used by automotive electronics to control the engine and other systems, and the signal to the speedometer is fed from the controller. On modern vehicles, the second method of connection is increasingly used.

Measuring speed with DSA is quite simple. The sensor generates a pulse signal (usually rectangular in shape), in which the pulse repetition rate depends on the speed of rotation of the shaft and, accordingly, on the speed of the car. Most modern sensors produce from 2000 to 25000 pulses per kilometer, but the most commonly used standard is 6000 pulses per kilometer (for contact sensors - 6 pulses per revolution of their rotor). Thus, the measurement of speed is reduced to the calculation by the controller of the repetition rate of pulses coming from the DSA per unit of time, and the translation of this value into km/h understandable to us.

Speed sensors are divided into two large groups:

● Directly driven by the shaft, or contact;

● Contactless.

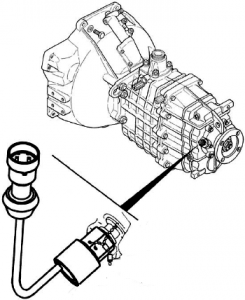

Installing a contact speed sensor at the gearbox

The first group includes sensors to which torque from the gearbox shaft, axle or transfer case is transmitted by means of a drive gear and a flexible steel cable (or a short rigid shaft). The sensor provides a device that reads the angular rotation of the shaft and converts it into electrical impulses. Sensors of this type are widely used, as they can be installed instead of the drive of a mechanical speedometer (which allows you to upgrade old vehicles at no extra cost) and are highly reliable.

Non-contact speed sensor master dial

The second group includes sensors that do not have direct contact with the rotating shaft. To measure the speed of such sensors, an auxiliary device is installed on the shaft - a master disc or rotor. Contactless devices are becoming more and more popular, they are installed on many current models of domestic cars.

All sensors operate on different physical principles. In contact devices, the Hall effect and the magnetoresistive effect (MRE), as well as optocouplers (optoelectronic pairs), are most often used. At the heart of non-contact sensors, the Hall effect is most widely used, and much less often MRE. The design and principle of operation of each type of sensor is described below.

Contact sensors based on the Hall effect

Sensors of this type are based on the Hall effect: if a flat conductor, through two opposite sides of which a direct current is passed, is placed in a magnetic field, then an electric voltage arises on its other opposite sides. At the heart of the DSA is a Hall chip, in which a wafer (usually made of permalloy) and an amplifier circuit are already integrated. In sensors, the microcircuit and magnet remain stationary, and the change in the magnetic field is carried out due to a rotating "curtain" - a ring with slots. The ring is connected to a drive cable or shaft, from which it receives rotation. The output signal from the DSA is sent to the speedometer or controller through a standard connector, through which power is supplied to the Hall chip.

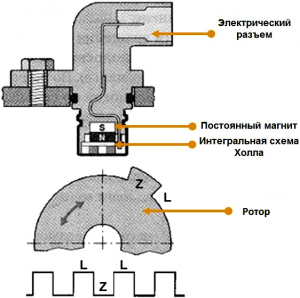

Non-contact sensors based on the Hall effect

Non-contact DSA is based on the same effect, but there are no moving parts in it - instead, a rotor or pulse disk with magnetized sections is located on the shaft of the unit (gearbox, axle gearbox). There is a small gap between the sensitive part of the sensor (with a Hall chip) and the rotor, when the rotor rotates, a pulse signal is generated in the microcircuit, which is sent to the controller through a standard connector.

Scheme of operation of a non-contact speed sensor

Contact sensors based on the magnetoresistive effect

Speed sensor design with magnetoresistive element

This type of DSA is based on the magnetoresistive effect - the property of some materials to change their electrical resistance when placed in a magnetic field. Such sensors are similar to Hall sensors, but they use chips with an integrated magnetoresistive element (MRE) based on semiconductor materials. Most often, these sensors have a direct drive, the change in the magnetic field is carried out by rotating the ring multi-pole magnet, the generated signal is supplied to the controller through a standard connector (through which the power supply of the microcircuit with MRE is provided).

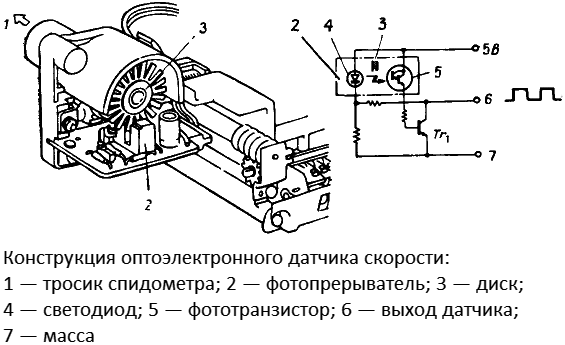

Optoelectronic contact sensors

These DSAs are the simplest in design, but they are less sensitive and more inertial than those described above. The sensor is based on an optocoupler - an LED and a phototransistor, between which there is a disk with slots connected to the drive shaft. When the disk rotates, the luminous flux between the LED and the phototransistor is periodically interrupted, these interrupts are amplified and sent to the controller in the form of a pulse signal.

Optoelectronic speed sensor design

How to choose and replace the right speed sensor

A faulty speed sensor in a modern vehicle can be a source of various problems - from the loss of data on the speed of movement and the distance traveled (the speedometer and odometer stop working), to the disruption of the power unit (unstable idling, increased fuel consumption, loss of power), power steering and security systems. Therefore, if the DSA breaks down, it should be replaced as soon as possible.

For replacement, you should take only the sensor that was on the car earlier, or use devices from among those recommended by the automaker. In some cases, it is possible to select a "non-native" DSA, but most often this is impossible - the sensor either does not fall into place, or gives incorrect readings during installation. Therefore, experiments with the selection of DSA should be resorted to only in extreme cases.

Replacement of the sensor is carried out in accordance with the instructions for this particular vehicle (or gearbox, axle or transfer case). Direct drive DSAs usually have a turnkey thread and hexagon (but not always - some products have a ring with transverse corrugation), so replacing them comes down to turning out the old device and screwing in a new one. Non-contact sensors are usually attached with one or two screws (bolts) threaded through a hole in the flange. In all cases, all work must be performed with the terminal removed from the battery, before dismantling the sensor, it is necessary to disconnect the electrical connector, and before installing a new one, clean the place of its installation.

It is more difficult to replace the rotor of non-contact sensors - for this it is necessary to partially disassemble the unit (box, bridge), and then carry out repair work in accordance with the instructions.

With the correct selection and replacement of the speed sensor, the speedometer and various car systems (including the engine) immediately start working. In the future, DSA will ensure safe and comfortable operation of the vehicle.

Post time: Jul-12-2023