Many modern engines still use gas distribution schemes with valve drives using rocker arms. Rocker arms are installed on a special part - the axis. Read about what the rocker arm axis is, how it works and works, as well as its selection and replacement in the article.

What is rocker arm axis?

The rocker arm axis is a part of the gas distribution mechanism of reciprocating internal combustion engines with overhead valves; A hollow rod that holds the rocker arms of the valves and related parts of the valve mechanism.

The rocker arm axis performs several functions:

• Correct positioning of rocker arms relative to camshaft tappets/cams and valves;

• Lubrication of friction surfaces of rocker arms and their bearings, oil supply to other elements of the gas distribution mechanism;

• Retention of rocker arms, their springs and other parts (the axle acts as a power load-bearing element).

That is, the rocker arm axis is the main load-bearing element for a number of timing parts (rocker arms, springs and some others) and one of the main oil lines of the unified engine lubrication system. This part is used only on overhead valve engines with a timing valve drive of various types:

- With a lower camshaft, with the actuation of valves through tappets, rods and rocker arms;

- With an overhead camshaft (common or separate shafts for each row of valves), with the actuation of valves through rocker arms;

- With an overhead camshaft, with valves driven through a lever pusher.

In modern engines with direct valve drive from camshaft cams, rocker arms and related parts are absent.

The rocker arm axis plays an important role in the operation of the engine, ensuring the normal functioning of its valve timing mechanism. A faulty or defective axle needs to be replaced as soon as possible, and in order to make the right choice of this part, you need to understand the existing types of axles, their designs and features.

Please note: today in the literature and trade enterprises, the term "rocker arm axis" is used in two meanings - as a separate part, a hollow tube on which rocker arms, springs and other parts are held, and as a complete axle with already installed supports, rocker arms and springs. In the future, we will talk about the axes of rocker arms in both of these senses.

Types, design and configuration of rocker arm axes

Axles are divided into several types according to the number of rocker arms installed and according to some design features.

According to the number of installed rocker arms, the axles are:

• Solo;

• Group.

An individual axle is a part that carries only one rocker arm and fasteners (thrust washer or nut). Individual rocker arm axles are used, as a rule, in engines with two valves per cylinder, so the number of axles in them is twice as large as the cylinders. Such an axis is made at the same time with the rack, so it is mounted on the cylinder head without additional parts, the whole structure is simpler and lighter. However, the individual axis of the rocker arms cannot be repaired in the event of a malfunction, it simply changes the assembly.

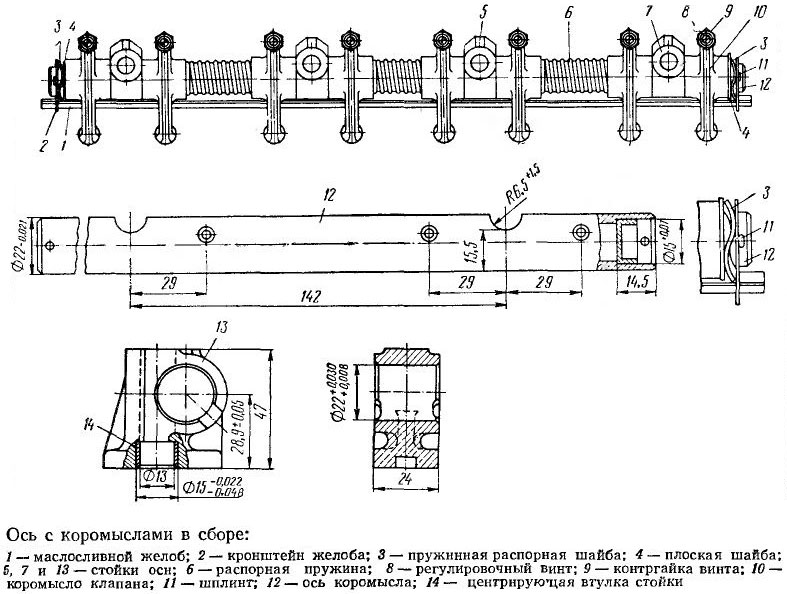

Axle with rocker arms assembly

A group axle is a part that carries several rocker arms and related parts (springs, thrust washers, pins). From 2 to 12 rocker arms can be located on one axle, depending on the engine design and the number of cylinders. So, on engines with separate cylinder heads, axles with two rocker arms are used for each cylinder, on some 6-cylinder engines with separate cylinder heads for three cylinders, two axles with six rocker arms are used on in-line 4, 5 and 6-cylinder engines, axles with 8, 10 and 12 rocker arms, respectively, etc. The number of group rocker arms in one in-line or V-shaped engine with a single cylinder head for a number of cylinders can be 1, 2 or 4. Motors with two valves per cylinder use one or two axles (in the case of a separate cylinder head), motors with four valves per cylinder use two or four axles. The number of axles in engines with individual cylinder heads corresponds to the number of heads.

The group axes of the rocker arms are simple. They are based on the axis itself - a steel shaft with a through longitudinal channel and a number of transverse holes according to the number of rocker arms installed. The extreme transverse holes are usually used to fix the axle in the racks with cotter pins and thrust washers. Since the axle is subjected to high loads, it is made of special grades of steel, and its surface is additionally subjected to chemical-thermal and heat treatment (carburization, hardening) to increase strength, resistance to wear and other negative influences.

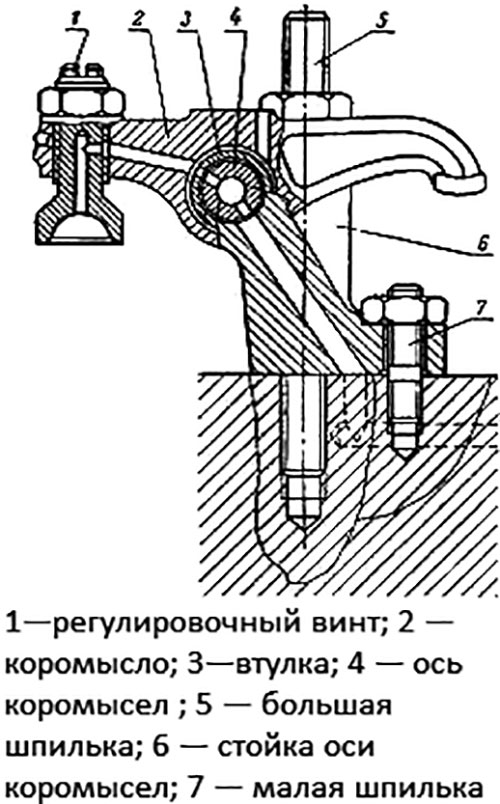

Rocker arms are mounted on the axle through bushings (plain bearings made of bronze or other materials), grooves and channels are made in the bushings for supplying oil from the axle to the rocker arms. Pairs of rocker arms are positioned by means of spacer cylindrical springs worn on the axle. The axle is mounted on the cylinder head using a series of racks - two extreme and several main (central) located between the rocker arms. The axle can be installed in racks freely or pressed into them. The rocker arm axles of four-valve engines can be mounted on twin struts, which ensure the correct positioning of timing parts. On the lower surfaces of the racks there are pins for centering and holes for studs / bolts for fastening.

The oil supply to the rocker arm axle can be carried out in two ways:

• Through one of the racks;

• Through a separate supply tube.

In the first case, one of the extreme or central struts has a channel through which oil flows from the corresponding cylinder head channel to the rocker arm axis. In the second case, a metal tube connected to the oil channel in the cylinder head is supplied from one end to the axis of the rocker arms.

In general, the axles of rocker arms of all types have a simple design, and therefore are reliable and durable, although these parts can fail - in this case, they need to be repaired or replaced.

The design of the rocker arm axis with oil supply through the central pillar

Issues of selection, repair and replacement of rocker arm axes

Like many other parts, rocker arm axes are often designed individually for a specific model range or even engine modification, which imposes restrictions on the choice of these parts. Therefore, for replacement, it is necessary to select only those axles that are recommended by the engine manufacturer itself - so there are guarantees that the new parts will fall into place and work normally.

Separately, it should be noted that even different modifications of one motor are often equipped with rocker arm axes that are different in design and characteristics. For example, some domestic power units for gasoline of different brands are equipped with cylinder heads that are not the same in design and dimensions, therefore, their rocker arm axes may differ (equipped with racks of different heights, rocker arms, etc.). This should be taken into account when buying spare parts and repairs.

The rocker arm axle must be dismantled and installed only in accordance with the instructions for repair and maintenance of the vehicle. The fact is that for the normal operation of the axle and the prevention of breakdowns, its fasteners (bolts or stud nuts) must be tightened in the correct sequence and with a certain effort. And after installation, it is imperative to adjust the temperature gap between the rocker arms and valves.

During the operation of the car, the rocker arm axle does not require special maintenance, it is only necessary in accordance with the instructions to check the interference of the bolts / nuts and inspect the axle parts for their integrity. Regular maintenance and proper operation of the vehicle guarantees reliable operation of the rocker arm axle and timing as a whole in all engine operating modes.

Post time: Aug-05-2023