The electric car starter is controlled by a special device located on its body - a retractor (or traction) relay. Read all about retractor relays, their design, types and principle of operation, as well as the correct selection and replacement of relays in the event of a breakdown.

What is a starter retractor relay?

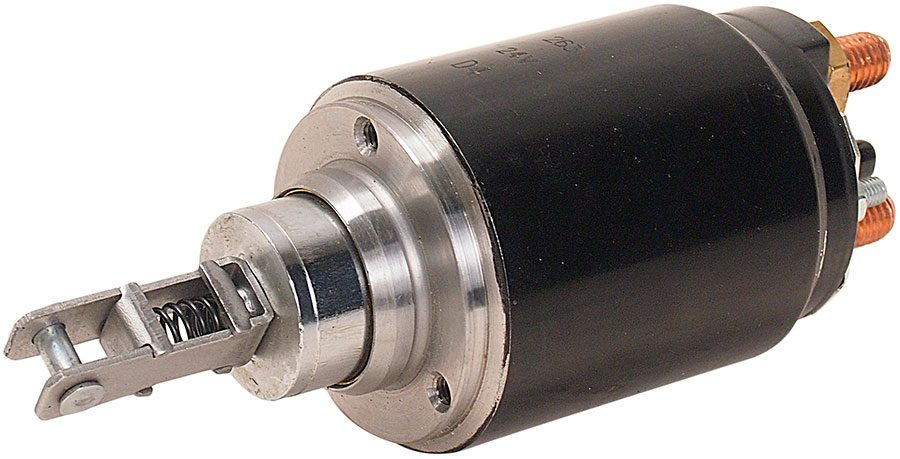

Starter retractor relay (traction relay) - assembly of an automobile electric starter; A solenoid combined with the contact group, which provides a connection of the starter motor to the battery and a mechanical connection of the starter to the flywheel crown when starting the engine.

The retractor relay enters the mechanical and electrical parts of the starter, controlling their joint operation. This node has several functions:

- Supply of the starter drive (bendix) to the gear ring of the flywheel when starting the engine and holding it until the ignition key is released;

- Connecting the starter motor to the battery;

- Retract the drive and turn off the starter when the ignition key is released.

Although the traction relay works as part of the starter, it is a separate unit that plays an important role in the operation of the engine start system. Any malfunction of this unit makes it much more difficult to start the engine or makes it impossible, so repairs or replacements must be performed as soon as possible. But before buying a new relay, you should understand its types, features and principle of operation

Design, types and features of retractor relays

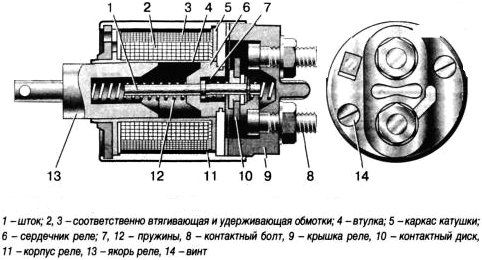

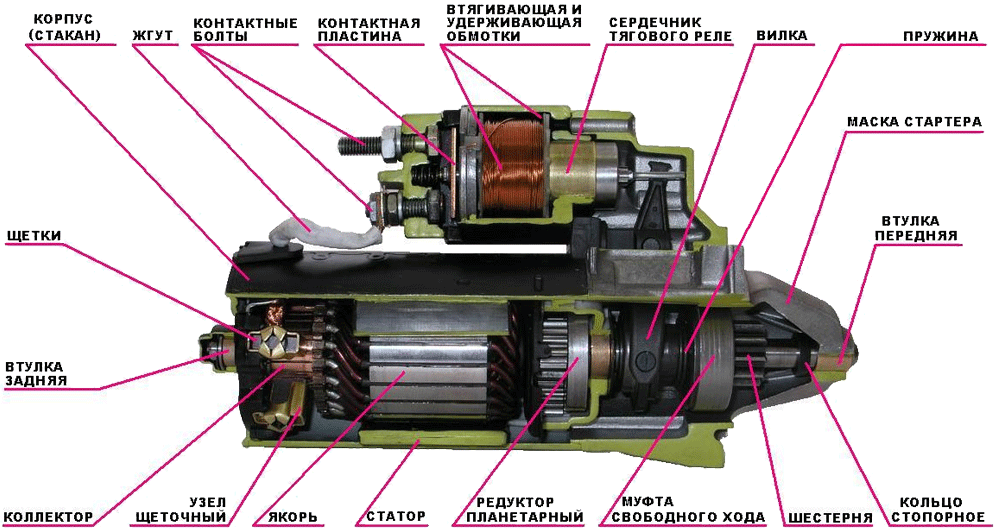

Currently, electric starters use retractor relays of the same design and principle of operation. This unit contains two interconnected devices - a power relay and a solenoid with a movable armature that turns it on (and at the same time brings the bendix to the flywheel).

The basis of the design is a cylindrical solenoid with two windings - a large retractor and a retaining one wound over it. On the back of the solenoid is a relay housing made of durable dielectric material. Contact bolts are located on the end wall of the relay - these are high-section terminals through which the starter is connected to the battery. Bolts can be steel, copper or brass, the use of such contacts is due to high currents in the starter circuit when starting the engine - they reach 400-800 A or more, and simple terminals with such a current would simply melt.

Wiring diagram of a retractor relay with an additional contact and an additional starter relay

When the contact bolts are closed, the retractor winding is shorted (its terminals close to each other), so it stops working. However, the retaining winding is still connected to the battery pack, and the magnetic field it creates is sufficient to hold the armature securely inside the solenoid.

After a successful start of the engine, the ignition key returns to its original position, as a result of which the retaining winding circuit breaks - in this magnetic field around the solenoid disappears and the armature is pushed out of the solenoid under the action of the spring, and the rod is removed from the contact bolts. The starter drive is removed from the flywheel crown and the starter is switched off. The traction relay and the entire starter are transferred to the position of readiness for a new start of the engine.

Issues of selection, repair and replacement of a retractor relay

The traction relay is subjected to significant electrical and mechanical loads, so there is a high probability of its failure even with careful operation. The malfunction of this unit is evidenced by various signs - the absence of a characteristic knock on the starter drive supply when the ignition is turned on, weak rotation of the starter when the battery is charged, the "silence" of the starter when the drive supply is running, and others. Also, malfunctions are detected when the relay runs - usually there are breaks in the windings, an increase in resistance in the power circuit due to burning and contamination of the contacts, etc. Often, the identified problems are difficult or impossible to eliminate (such as a break in the retractor or retaining windings, breakage of the contact bolt, and some others), so it is easier and cheaper to completely replace the relay.

The general device of the electric starter and the place of the retractor relay in it

Only those types and models of retractor relays specified by the vehicle manufacturer should be selected for replacement. The purchase must be made by catalog numbers - this is the only way to confidently change the node and make the starter work normally. It is difficult or impossible to install a relay of another type (due to unequal dimensions), and if this can be done, the starter may not work correctly or not perform its main function at all.

To replace the relay, the electric starter has to be dismantled from the engine and disassembled, often using a special tool. When installing a new relay, electrical connections must be carefully made - the wires are pre-stripped and twisted, when fixing them on the terminals, reliability must be ensured by preventing sparking and heating. All operations are best performed in accordance with the recommendations prescribed by the automaker in the instructions for repair and maintenance of the vehicle.

In the future, the traction relay, like the starter itself, requires only periodic inspection and verification in accordance with the maintenance regulations. With the right selection and replacement, this unit will work reliably and efficiently, ensuring a confident start of the engine.

Post time: Aug-05-2023