In any vehicle there are systems and assemblies that require control of gas or liquid pressure - wheels, engine oil system, hydraulic system and others. To measure the pressure in these systems, special devices are designed - pressure gauges, the types and applications of which are described in the article.

What is a pressure gauge

A car pressure gauge (from the Greek "manos" - loose, and "metreo" - measuring) is a device for measuring the pressure of gases and liquids in various systems and units of vehicles.

For the normal and safe operation of cars, buses, tractors and other equipment, it is necessary to control the pressure of gases and liquids in various systems - air in tires, wheels and pneumatic systems, oil in the engine and hydraulic system, and others. To solve this problem, special devices are used - pressure gauges. According to the readings of the pressure gauge, the driver judges the serviceability of these systems, adjusts their operating modes or decides on repairs.

For correct pressure measurement, it is necessary to use a pressure gauge with the appropriate characteristics. And in order to make a choice of such a device, you should understand their existing types and features.

Types and design of pressure gauges

Two types of pressure measuring instruments are used in automobiles:

● Pressure gauges;

● Pressure gauges.

Pressure gauges are devices with a built-in sensing element that interacts with the medium whose pressure needs to be measured. In motor vehicles, pneumatic pressure gauges are most often used to measure the air pressure in the tires of the wheels and the pneumatic system, as well as to assess the compression in the engine cylinders. Oil pressure gauges are used less frequently, they can be found on equipment with a developed hydraulic system.

Pressure gauges are devices in which the sensing element is made in the form of a remote sensor. The pressure is measured by a sensor that converts a mechanical quantity into an electrical one. The electrical signal obtained in this way is sent to the pressure gauge of the pointer or digital type. Pressure gauges can be oil and pneumatic.

All devices are divided into two groups according to the method of measuring and displaying information:

● Mechanical pointers;

● Electronic digital.

Mechanical tire pressure gauge

Electronic tire pressure gauge

Both types of pressure gauges have a fundamentally identical device. The basis of the device is a sensitive element that is in contact with the medium and perceives its pressure. A transducer is associated with a sensing element - a device that converts one mechanical quantity (medium pressure) into another mechanical quantity (arrow deflection) or into an electronic signal. An indication device is connected to the converter - an arrow with a dial or an LCD display. All these components are placed in the housing, on which the fitting and auxiliary parts (buttons or levers for pressure relief, handles, metal rings and others) are located.

In motor transport, two types of deformation-type mechanical pressure gauges (spring) are used - based on a tubular (Bourdon tube) and box-shaped (bellows) springs.

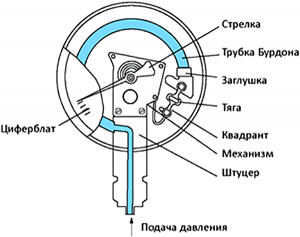

The basis of the device of the first type is a sealed metal tube in the form of a half ring (arc), one end of which is rigidly fixed in the case, and the second is free, it is connected to the converter (transmission mechanism). The transducer is made in the form of a system of levers and springs connected to the arrow. The tube is connected to a fitting that is connected to the system to measure the pressures in it. As the pressure increases, the tube tends to straighten, its free edge rises and pulls the levers of the transmission mechanism, which, in turn, deflect the arrow. The position of the arrow corresponds to the amount of pressure in the system. When the pressure decreases, the tube returns to its original position due to its elasticity.

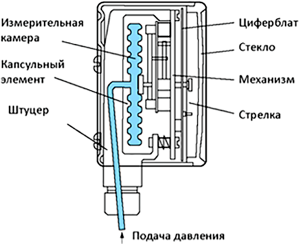

The basis of the device of the second type is a corrugated metal box (bellows) of cylindrical shape - in fact, these are two corrugated round membranes connected by a thin belt. In the center of one base of the box there is a supply tube ending in a fitting, and the center of the second base is connected by a lever of the transmission mechanism. As the pressure increases, the diaphragms diverge from each other, this displacement is fixed by the transmission mechanism and is displayed by moving the arrow along the dial. When the pressure decreases, the membranes, due to their elasticity, shift again and take their original position.

The device of the pressure gauge with a tubular spring

(Bourdon tube)

The device of the pressure gauge with a box spring

(chamber)

Electronic pressure gauges can be equipped with spring-type sensing elements, but today special compact pressure sensors are more often used that convert the pressure of a gas or liquid into an electronic signal. This signal is converted by a special circuit and displayed on a digital indicator.

Functionality, characteristics and applicability of pressure gauges

Pressure gauges designed for automotive equipment can be divided into several types according to their purpose:

● Portable and stationary tires - for measuring air pressure in tires;

● Portable pneumatic to check the compression in the engine cylinders;

● Pneumatic stationary for measuring pressure in pneumatic systems;

● Oil to measure the oil pressure in the engine.

Depending on the applicability of pressure gauges, different types of fittings and housing design are used. Portable devices usually have impact-resistant housings and threadless (attached) fittings, which, to ensure tightness, must be tightly pressed against the wheel valve, engine head, etc. In stationary devices, threaded fittings with an additional seal are used, in such pressure gauges and pressure gauges, backlight lamps and connectors for their connection can also be located.

The devices may have various auxiliary functions:

● The presence of an extension steel tube or a flexible hose;

● The presence of a valve for fixing the measurement result (accordingly, there is also a button for relieving pressure and zeroing the device before a new measurement);

● The presence of deflators - adjustable valves for controlled pressure reduction with simultaneous control by a pressure gauge;

● Various additional features of electronic devices - backlight, sound indication and others.

As for the characteristics, two of them are important for automotive pressure gauges - the ultimate pressure (the range of measured pressures) and the accuracy class.

Pressure is measured in kilogram-forces per square centimeter (kgf/cm²), atmospheres (1 atm = 1 kgf/cm²), bars (1 bar = 1.0197 atm.) and pound-forces per square inch (psi, 1 psi = 0.07 atm.). On the dial of the pressure gauge, the unit of measurement must be indicated, on some pointer pressure gauges there are two or three scales at once, calibrated in different units of measurement. In electronic pressure gauges, you can find the function of switching the unit of measurement displayed on the display.

Pressure gauge with deflator

The accuracy class determines the error that the pressure gauge introduces during measurement. The accuracy class of the device corresponds to one greatness from the range of 0.4, 0.6, 1.0, 1.5, 2.5 and 4.0, the smaller the number, the higher the accuracy. These figures indicate the maximum error as a percentage of the measuring range of the device. For example, a tire pressure gauge with a measurement limit of 6 atmospheres and an accuracy class of 0.5 can "deceive" only 0.03 atmospheres, but the same pressure gauge of accuracy class 2.5 will give an error of 0.15 atmospheres. The accuracy class is usually indicated on the dial of the device, this number may be preceded by the letters KL or CL. Accuracy classes of pressure gauges must comply with GOST 2405-88.

How to choose and use a pressure gauge

When buying a pressure gauge, it is necessary to take into account its type and features of operation. The easiest way is to choose a pressure gauge built into the dashboard of the car - in this case, you need to use a device of the type and model that is recommended by the automaker. The choice of stationary pressure gauges for hydraulic and pneumatic systems is also simple - you need to use a device with a suitable type of fitting and pressure measurement range.

The choice of tire pressure gauges is much wider and more diverse. For passenger cars, a device with a measurement limit of up to 5 atmospheres is sufficient (since the normal tire pressure is 2-2.2 atm., and in the "stowaways" - up to 4.2-4.3 atm.), for trucks, a device for 7 or even 11 atmospheres may be required. If you often have to change the tire pressure, it is better to use a pressure gauge with a deflator. And to measure the pressure in the gable wheels of trucks, a device with an extension tube or hose will be an excellent solution.

Measurements with a pressure gauge should be carried out in accordance with the instructions attached to it. When measuring, it is important to ensure that the device fitting is securely pressed against the counter fitting or hole, otherwise the accuracy of the readings may deteriorate due to air leaks. Installation of stationary pressure gauges is allowed only after the pressure in the system has been released. With the right choice and use of the pressure gauge, the driver will always have information about the air and oil pressure, and will be able to take timely troubleshooting measures.

Post time: Jul-12-2023