Every vehicle with an internal combustion engine shall be equipped with an exhaust system. One of the main mounting products of this system is the silencer clamp - read all about the clamps, their types, design and applicability, as well as their correct selection and replacement, in the article.

What is a muffler clamp?

The muffler clamp is a component of the exhaust system of vehicles with internal combustion engines; A ring, plate or other design for connecting exhaust system parts to brackets or to each other.

Clamps, despite their simple design and invisibility, solve several important tasks in the exhaust system of a car:

● Clamps for screed of individual parts of the system - ensure the reliability and tightness of detachable joints, without requiring the use of welding and other installation methods;

● Ensuring the reliability of fastening of all components to each other and to the load-bearing elements of the car body/frame;

● Prevention of vibrations and excessive amplitude of vibrations of parts of the exhaust system during the movement of the car and in various operating modes of the power unit.

Often, the breakdown of the muffler clamp becomes a real headache for the car owner (this increases vibrations, exhaust pipes become a source of noise and rattling, and even there is a possibility of losing the muffler), so this part should be replaced as soon as possible. But before buying a new clamp, you should understand the features, design and applicability of these components.

Types, design and characteristics of muffler clamps

Muffler clamps used in vehicles are divided into three groups according to their purpose (applicability):

● Clamps for connection (screed) of individual components of the exhaust system - pipes, resonators, converters, flame arresters and others;

● Clamps for mounting parts of the exhaust system on the load-bearing elements of the frame or car body;

● Clamps used simultaneously for tie parts and their installation on load-bearing elements.

Clamps for various purposes differ in design, applicability and characteristics.

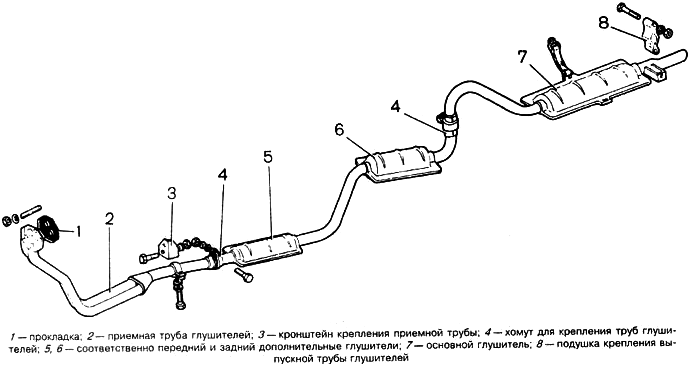

The exhaust system and the place of muffler clamps in it

Connecting clamps

These clamps ensure the tightness of the exhaust tract, their number in the exhaust system can be from one to three, they are used in places where flange connections can be abandoned.

There are three main types of clamps for connecting exhaust system parts:

● Detachable two-sector (shoe);

● Detachable stepladder clamps;

● One-piece clamps with a split bracket;

● All-in-one tubular.

Two-sector detachable muffler clamp

The two-sector detachable clamp consists of two halves tightened with screws (bolts), between which there is a metal support ring. The ring can be smooth for installation on conventional pipes, and profile for installation on pipes with a special joint profile (in the form of sockets). These products are used to connect pipes butt-to-end, they provide a reliable connection of parts and at the same time compensate for some displacements of their axes when the vehicle is moving. Most widely used in domestic cars.

A detachable stepladder clamp consists of a stepladder (U-shaped stud of circular cross-section), at both ends of which a thread for nuts is cut, and a curly or straight bracket put on it. Stepladder clamps are used to install overlapping pipes without the need to connect them before installation. This is the simplest and at the same time quite reliable solution for connecting pipes of various diameters.

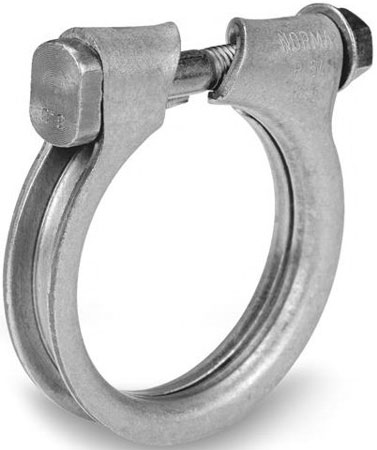

A one-piece clamp with a split bracket is a steel round bracket of a complex profile, in the section of which there is a transverse tightening screw (bolt). The bracket to achieve the required rigidity can have a U-shaped or box-shaped section, so it can move apart within very small limits. These products are used to connect overlapping pipes, thanks to the ring profile, they provide high reliability of installation. Most often, clamps of this design are used on foreign cars.

One-piece muffler clamp with split bracket

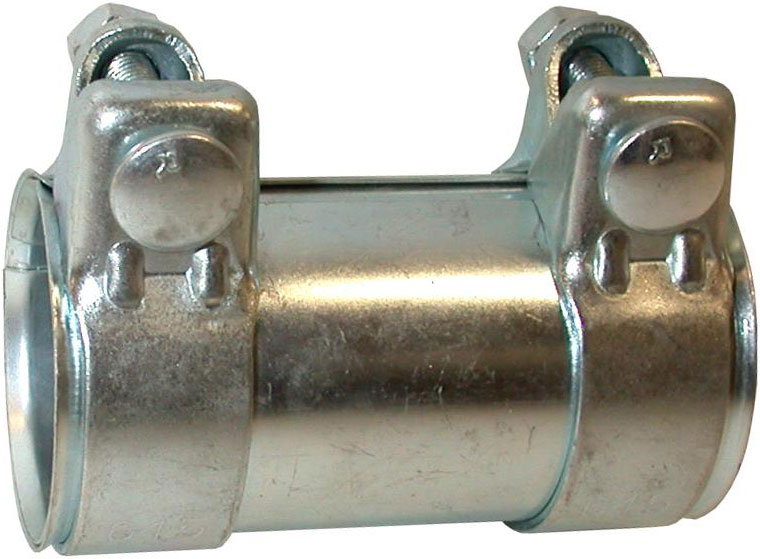

Tubular exhaust pipe clamp

Tubular clamps are made in the form of a short pipe with a longitudinal cut (or two split pipes inserted into each other) with two split clamps at the edges. This type of clamp can be used to connect pipes end-to-end and overlap, ensuring high reliability and tightness of installation.

Mounting clamps

Mounting clamps are used to hang the exhaust tract and its individual parts under the frame / body of the car. Their number in the system can be from one to three or more. These muffler clamps are of three main types:

- Split staples of various types and shapes;

- Detachable two-sector;

- Halves of detachable two-sector clamps.

Split brackets are the most versatile and common clamps that are used to mount pipes, mufflers and other parts of the exhaust system on load-bearing elements. In the simplest case, the clamp is made in the form of a tape bracket of a round profile with eyelets for tightening with a screw (bolt). Staples can be narrow and wide, in the latter case they have a longitudinal stiffener and are clamped with two screws. Often, such brackets are made in the form of U-shaped parts or parts of a round profile with eyelets increased in length - with their help, parts of the exhaust system are suspended from the frame / body at some distance.

Detachable two-sector clamps are made in the form of two halves in the form of tapes or strips, each of which has two eyes for mounting with screws (bolts). With the help of products of this type, it is possible to install mufflers and pipes in hard-to-reach places or where it is difficult to install conventional split brackets.

The halves of the split two-sector clamps are the lower halves of the previous type of clamps, their upper part is made in the form of a removable or non-removable bracket mounted on the frame / body of the vehicle.

Universal clamps

This group of products includes clamps, staples, which can simultaneously play the role of a mounting and connecting clamp - they provide sealing of pipes and at the same time hold the entire structure on the frame / body of the car.

Design features and characteristics of muffler clamps

Clamps are made of steels of various grades - mainly structural, less often - from alloyed (stainless steel), for additional protection they can be galvanized or nickel plated / chrome plated (chemical or galvanic). The same applies to the screws/bolts that come with the clamps.

As a rule, clamps are made by stamping from steel billets (tapes). Clamps can have different sizes, corresponding to a standard and non-standard range of pipe diameters. Mounting clamps of mufflers, as a rule, have a complex shape (oval, with protrusions), corresponding to the cross-section of the muffler, resonator or converter of the vehicle. All this should be taken into account when selecting a new part for the car.

Issues of selection and replacement of the muffler clamp

Clamps operate in difficult conditions, constantly exposed to significant heating and temperature changes, exposure to exhaust gases, as well as water, dirt and various chemical compounds (salts from the road and others). Therefore, over time, even clamps made of alloy steels lose strength and can cause exhaust leaks or damage to the integrity of the exhaust tract. In case of breakage, the clamp must be replaced, it is also recommended to change these parts when replacing individual parts or the entire exhaust system of the car.

The muffler clamp should be chosen in accordance with its purpose and the diameter of the pipes / mufflers to be connected. Ideally, you need to use a clamp of the same type and catalog number that was installed on the car earlier. However, in many cases, a replacement that can improve the performance of the system is acceptable. For example, it is quite justified to replace the stepladder clamp with a split one-piece clamp - it will provide better tightness and increased installation strength. On the other hand, sometimes it is impossible to replace - for example, it is often impossible to replace a two-sector detachable clamp with any other, since the shape of the end parts of the connected pipes can be adjusted to it.

When selecting clamps, you should remember about the features of their installation. The stepladder clamp is the easiest to install - it can be installed on already assembled pipes, since the stepladder is disconnected from the crossbar and then tightened with nuts. This is fully true for two-sector clamps. And to install one-piece split or tubular clamps, the pipes will first have to be disconnected, inserted into the clamp and only then installed. Some difficulties may arise when installing universal clamps, since in this case it is necessary to simultaneously keep the parts connected to each other and place them at the right distance from the frame / body.

When mounting the clamp, it is necessary to ensure the correct installation of its installation and the reliability of tightening the screws - only in this case the connection will be strong, reliable and durable.

Post time: Aug-05-2023