The bulk of the mounted units installed on the engines of MTZ (Belarus) tractors has a classic belt drive based on a V-belt. Read all about MTZ belts, their design features, types, characteristics and applicability, as well as their correct selection and replacement.

What is an MTZ belt?

MTZ belt - endless (ring) rubber belts of wedge cross-section, used to transmit torque from the crankshaft to the pulleys of mounted units of tractor engines manufactured by the Minsk Tractor Plant (MTZ, Belarus).

On the basis of the V-belt transmission, drives of various equipment are built, which should work when the engine is running: a water pump, a cooling fan, an electric generator, a pneumatic compressor and an air conditioner compressor. The belt drive is implemented by means of pulleys mounted on the engine crankshaft and shafts of the units, and a rubber belt of the appropriate profile and length. This drive is simple and reliable, but the belt is subject to wear and damage, so it must be replaced regularly. For the correct selection of the belt, it is necessary to know about the types of these products used on MTZ tractors, their characteristics and applicability.

Types, features and applicability of MTZ belts

On the power units of the equipment of the Minsk plant, standard rubber belts are used, which differ in cross-section, profile, type of cord, size and applicability.

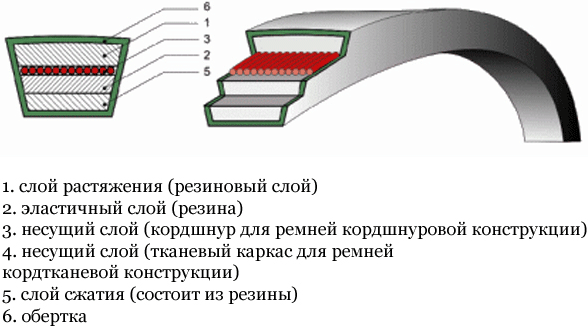

All belts have a standard design. They are based on a load-bearing layer - cordcord, placed inside the body of the belt made of vulcanized rubber in one way or another, and the outer surface is protected by a wrapping fabric. According to the type of load-bearing layer, belts are divided into two groups:

● With polyamide (nylon) cordcord;

● With polyester cord.

MTZ belts are V-belts - their cross-section is a wedge with a flat or slightly convex wide base and a straight narrow base. Products are divided into two types according to the ratio of width and height:

● Type I - belts of narrow cross-section;

● Type II - belts of normal cross-section.

Moreover, products of both sections can have a different profile (type of narrow base):

● Smooth belt - with a straight narrow base;

● Timing belt - transverse threaded teeth are made on a narrow base.

V-belt structure

Timing belts are more elastic and have a smaller bending radius, which achieves increased reliability of the belt drive. However, in the body of smooth belts, the loads are distributed more evenly, so they are more durable, especially in conditions with increased mechanical and thermal loads.

MTZ tractors use a wide range of belts, which are divided into several groups according to applicability:

● For tractors with engines of the D-242, D-243, D-245 lines (early and current models MTZ-80/82, 100/102, basic models Belarus-550, 900, 1025, 1220.1);

● For tractors with engines of the D-260, D-265 lines (basic models Belarus-1221, 1502, 1523, 2022);

● For tractors with Lombardini engines (basic models Belarus-320, 622).

According to the purpose, belts are divided into the following types:

● Water pump drive (belt with a cross section of 16×11 mm, a length of 1220 mm, smooth);

● Water pump and fan drive (belt with a cross section of 11×10 mm, 1250 mm smooth, and toothed);

● Pneumatic compressor drive (belt with a cross section of 11×10 mm, length of 1250 mm smooth and toothed, belt with a cross section of 11×10 with a length of 875 mm toothed for Lombardini engines);

● The drive of the air conditioner compressor (belt with a cross section of 11×10 mm, a length of 1650 mm);

● Generator drive (belt with a cross section of 11×10 mm, length 1180 mm smooth and toothed, belt with a cross section of 11×10 mm, length 1150 mm toothed, belt with a cross section of 11×10 mm, length 975 mm toothed for Lombardini engines).

The most popular belts are presented in two versions - smooth and toothed, having a different climatic design. Timing belts are designed for use in regions with tropical and temperate climates (versions "T" and "U" of various categories with an operating temperature of up to + 60 ° C), and smooth belts - for use in all regions, including those with cold climates (version "HL" of various categories, with an operating temperature of up to -60 ° C). This must be taken into account when choosing a new belt.

Here we note that all MTZ belts are so-called fan belts that meet the requirements of GOST 5813-2015 (and its earlier versions). The name "fan" should not be confusing - these rubber products are universal drive belts that can be used in drives of various units.

The belt drive of mounted engine units can be single-row and double-row. In the first case, the unit has only one V-pulley and a drive on one belt. In the second case, a double (two-strand) pulley is installed on the unit and the crankshaft, along which two V-belts are passed. The double-row V-belt transmission is more reliable, this placement of the belts prevents them from twisting and reduces the likelihood of slippage when starting the engine and at high speeds. Today, on various engines, which are equipped with MTZ tractors, you can find both drive options.

Issues of selection and replacement of MTZ belts

V-belts are exposed to environmental influences (especially in MTZ tractors of model ranges 80, 320, 422, 550, 622, 1025, 1221 with their characteristic open engine compartment), high temperatures and significant mechanical loads, so over time they become cracked, stretched, exfoliated and cease to perform their functions. In all these cases, the belt should be replaced.

The choice of a belt for a tractor is not too difficult - the new product must have the same cross-section and length as the old one. Usually, the dimensions of the belts are indicated on their non-working (wide) surface, you can also find out the characteristics of the belt from the instructions or from the catalog of spare parts for the engine or tractor. It must be remembered that products with a cross section of 11×10 mm are belts with a narrow cross-section (type I), products with a section of 16×11 are belts with a normal cross-section (type II), and they are not interchangeable. Therefore, if you need a drive belt for the water pump of the D-242 engine, then a similar belt from the D-260 engine cannot be put in its place, and vice versa.

If the engine uses a double V-belt drive, it is recommended to change both belts at once, otherwise the old belt remaining in the pair may soon become a source of problems again.

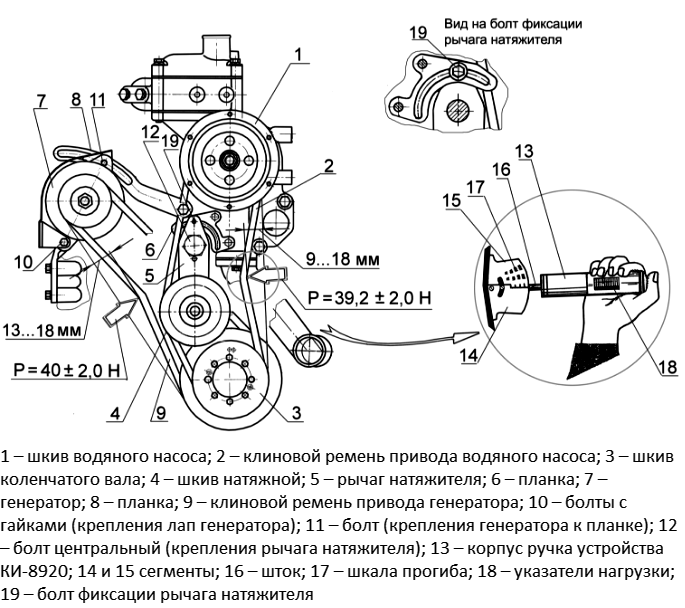

An example of installing and adjusting the tension of the alternator belts and the water pump of the D-260 engine

Particular attention should be paid to the choice of belts for tractors in accordance with the climatic conditions of their preferential regions of operation. For equipment operating in cold climates, only smooth belts in the "HL" version are suitable. The installation of timing belts in the "T" or "U" version in winter can cause breakage - such a belt becomes too stiff in the cold, cracks and collapses even with minor loads. For tractors operated in regions with a warm climate, on the contrary, it is better to use belts in tropical design, including toothed ones - they better resist heat and have a minimum coefficient of expansion, which prevents their excessive elongation at high temperatures.

As a rule, replacing belts on MTZ tractors is not difficult - in most cases it is necessary to reduce its tension by loosening the fastening of the unit (usually the generator) or the tensioning device, remove the old belt, put a new one and adjust the tension. The new belt must have the tension recommended by the engine manufacturer and specified in the relevant instructions. For proper belt tension, it is recommended to use a special device with a dynamometer. Adjustment "by eye" is unacceptable - with a weak tension, the belts will slip (which is completely unacceptable for some units, for example, for a water pump, since the engine in this case will overheat) and wear out intensively, and with strong tension, the belt will stretch and contribute to intensive wear of bearings and other parts of the units.

The right choice, installation and adjustment of MTZ drive belts is the key to reliable operation of the engine and the entire tractor in any conditions.

Tubular exhaust pipe clamp

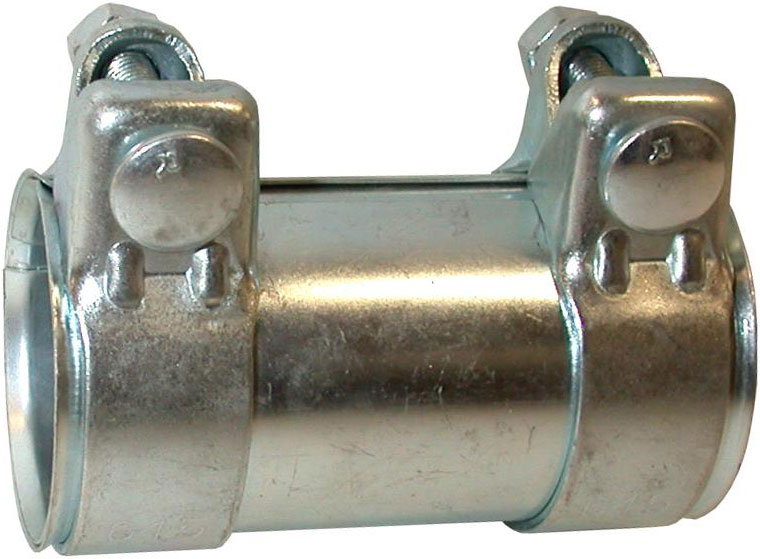

Tubular clamps are made in the form of a short pipe with a longitudinal cut (or two split pipes inserted into each other) with two split clamps at the edges. This type of clamp can be used to connect pipes end-to-end and overlap, ensuring high reliability and tightness of installation.

Mounting clamps

Mounting clamps are used to hang the exhaust tract and its individual parts under the frame / body of the car. Their number in the system can be from one to three or more. These muffler clamps are of three main types:

- Split staples of various types and shapes;

- Detachable two-sector;

- Halves of detachable two-sector clamps.

Split brackets are the most versatile and common clamps that are used to mount pipes, mufflers and other parts of the exhaust system on load-bearing elements. In the simplest case, the clamp is made in the form of a tape bracket of a round profile with eyelets for tightening with a screw (bolt). Staples can be narrow and wide, in the latter case they have a longitudinal stiffener and are clamped with two screws. Often, such brackets are made in the form of U-shaped parts or parts of a round profile with eyelets increased in length - with their help, parts of the exhaust system are suspended from the frame / body at some distance.

Detachable two-sector clamps are made in the form of two halves in the form of tapes or strips, each of which has two eyes for mounting with screws (bolts). With the help of products of this type, it is possible to install mufflers and pipes in hard-to-reach places or where it is difficult to install conventional split brackets.

The halves of the split two-sector clamps are the lower halves of the previous type of clamps, their upper part is made in the form of a removable or non-removable bracket mounted on the frame / body of the vehicle.

Universal clamps

This group of products includes clamps, staples, which can simultaneously play the role of a mounting and connecting clamp - they provide sealing of pipes and at the same time hold the entire structure on the frame / body of the car.

Design features and characteristics of muffler clamps

Clamps are made of steels of various grades - mainly structural, less often - from alloyed (stainless steel), for additional protection they can be galvanized or nickel plated / chrome plated (chemical or galvanic). The same applies to the screws/bolts that come with the clamps.

As a rule, clamps are made by stamping from steel billets (tapes). Clamps can have different sizes, corresponding to a standard and non-standard range of pipe diameters. Mounting clamps of mufflers, as a rule, have a complex shape (oval, with protrusions), corresponding to the cross-section of the muffler, resonator or converter of the vehicle. All this should be taken into account when selecting a new part for the car.

Issues of selection and replacement of the muffler clamp

Clamps operate in difficult conditions, constantly exposed to significant heating and temperature changes, exposure to exhaust gases, as well as water, dirt and various chemical compounds (salts from the road and others). Therefore, over time, even clamps made of alloy steels lose strength and can cause exhaust leaks or damage to the integrity of the exhaust tract. In case of breakage, the clamp must be replaced, it is also recommended to change these parts when replacing individual parts or the entire exhaust system of the car.

The muffler clamp should be chosen in accordance with its purpose and the diameter of the pipes / mufflers to be connected. Ideally, you need to use a clamp of the same type and catalog number that was installed on the car earlier. However, in many cases, a replacement that can improve the performance of the system is acceptable. For example, it is quite justified to replace the stepladder clamp with a split one-piece clamp - it will provide better tightness and increased installation strength. On the other hand, sometimes it is impossible to replace - for example, it is often impossible to replace a two-sector detachable clamp with any other, since the shape of the end parts of the connected pipes can be adjusted to it.

When selecting clamps, you should remember about the features of their installation. The stepladder clamp is the easiest to install - it can be installed on already assembled pipes, since the stepladder is disconnected from the crossbar and then tightened with nuts. This is fully true for two-sector clamps. And to install one-piece split or tubular clamps, the pipes will first have to be disconnected, inserted into the clamp and only then installed. Some difficulties may arise when installing universal clamps, since in this case it is necessary to simultaneously keep the parts connected to each other and place them at the right distance from the frame / body.

When mounting the clamp, it is necessary to ensure the correct installation of its installation and the reliability of tightening the screws - only in this case the connection will be strong, reliable and durable.

Post time: Aug-05-2023