In vehicles equipped with hydraulically operated braking systems, brake fluid is stored in a special container - the reservoir of the master brake cylinder. Read all about GTZ tanks, their design, existing types and features, as well as the selection and replacement of these parts in the article.

Purpose and functions of the GTZ tank

GTZ tank (master brake cylinder tank, GTZ expansion tank) is a component of the master brake cylinder of a hydraulically driven brake system; a container for storing brake fluid and supplying it to the GTZ during the operation of the brake system.

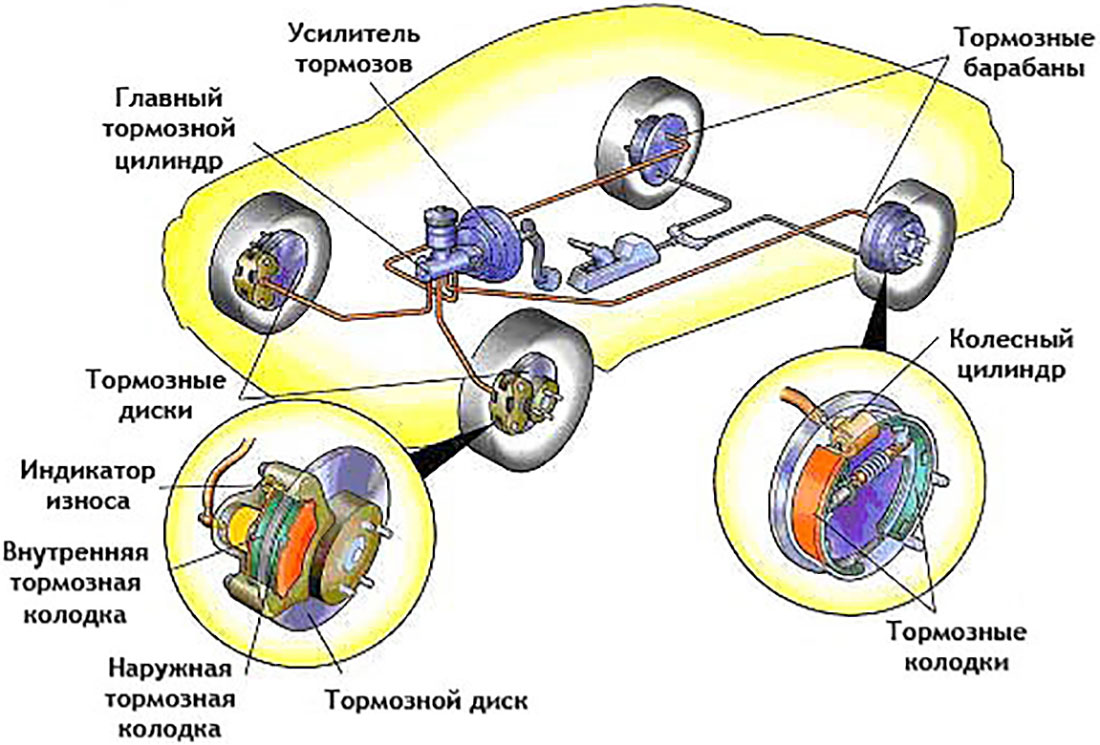

Passenger cars, commercial trucks and many medium-duty trucks are equipped with hydraulically actuated wheel brake systems. In general, such a system consists of a brake master cylinder (GTZ), through a vacuum or pneumatic amplifier associated with the brake pedal, and working brake cylinders (RTC) in the wheel brakes connected to the GTZ by a piping system. A special brake fluid operates in the system, which ensures the transfer of force from the GTZ to the RTC and, thereby, the brakes are deployed. To store the fluid supply in the system, a special element is used - the reservoir of the master brake cylinder.

General diagram of the hydraulically actuated brake system

The GTZ tank solves several main tasks:

● It acts as a container for storing a supply of brake fluid;

● Compensates for the thermal expansion of the liquid;

● Compensates for minor fluid leaks in the system;

● Provides fluid supply to the GTZ during system operation;

● Performs service functions - monitoring the level of brake fluid and its replenishment, signaling a dangerous decrease in the fluid level.

The GTZ tank is extremely important for the normal operation of the brake system, and hence for the safety of the entire car. Therefore, in case of any malfunctions, this part must be repaired or replaced in a timely manner. To make the right replacement, you should understand the existing types of GTZ tanks and their features.

Types, design and features of GTZ tanks

The currently used GTZ tanks are divided into two large groups:

● Single-section;

● Two-section.

Single-section GTZ tank

Two-section GTZ tank

Single-section tanks are installed on both single-section and two-section GTZ of trucks and cars. Single-section cylinders combined with a pneumatic or vacuum brake booster are used in medium-duty trucks, there can be two of them (one GTZ for the front and rear axle contours) or three (one GTZ for the front axle contour and one for each rear wheel). Accordingly, in one such car there may be two or three single-section tanks.

In some domestic cars (a number of UAZ and GAZ models), two-section GTZ with two single-section tanks are used, each of which works for its own section and is not connected to the other. However, this solution has a number of drawbacks, including the complexity of the system and a decrease in its reliability. On the other hand, the presence of two tanks ensures the independent operation of the brake system circuits, therefore, if fluid leaks from one circuit, the second will provide the ability to control the vehicle.

Two-section tanks are installed only on two-section GTZ of cars and trucks. Such tanks have increased dimensions and two fittings for connecting to the cylinder sections. In all vehicles with two-section GTZ, only one two-section tank is installed. Tanks with two sections simplify the design of the entire system and provide fluid bypass between circuits, which eliminates the failure of one of them.

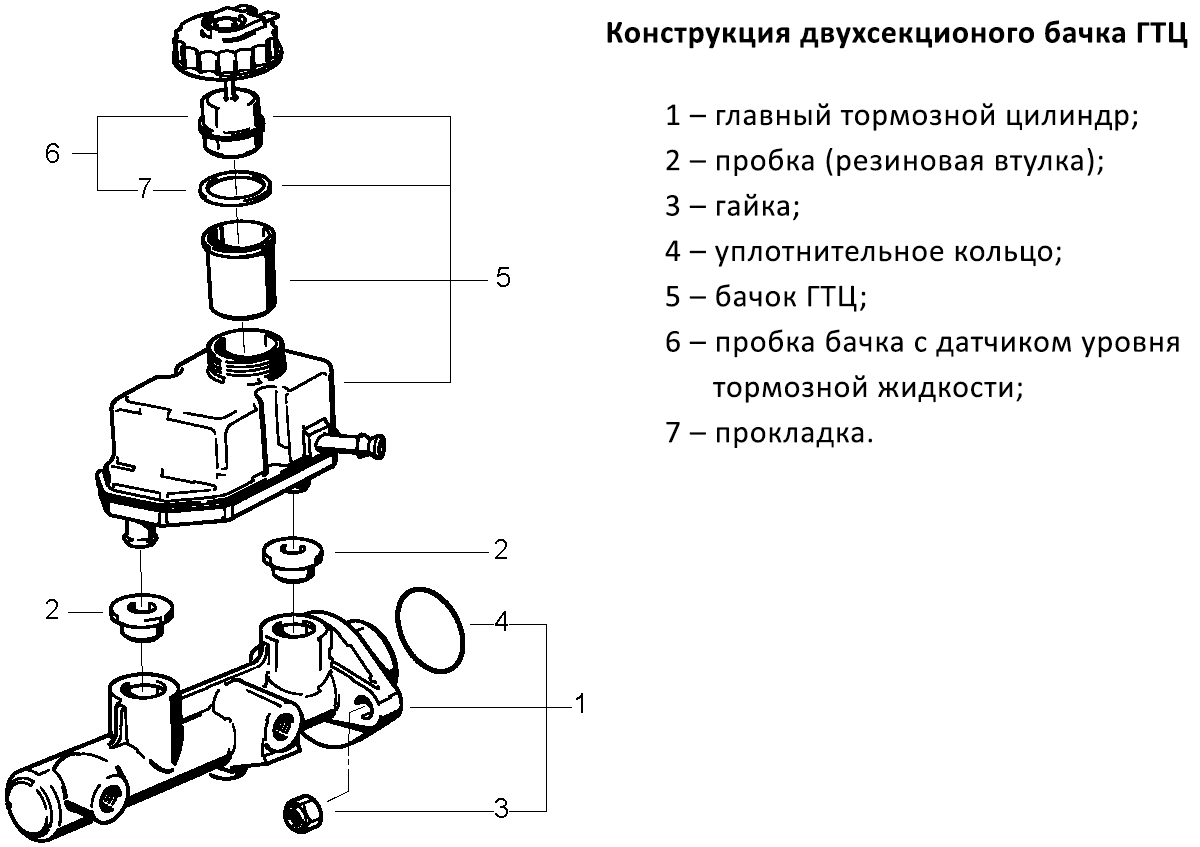

Structurally, all GTZ tanks are quite simple and differ only in details. The tanks are plastic (most often made of white translucent plastic, which makes it easier to track the liquid level), one-piece or made of two cast halves, in the upper part there is a threaded or bayonet filler neck, closed with a stopper, in the lower part there are fittings. In most tanks, the fittings are molded from plastic, but in single-section tank trucks, a metal threaded fitting is more often used. On the side surface there may be a translucent window with marks of the maximum and minimum liquid level. In some cases, additional fasteners are provided - brackets or eyelets. In the two-section GTZ tanks, a low-height partition is located between the sections, which prevents the complete flow of liquid from one half to the other when the car overcomes slopes or when driving on uneven road surfaces.

Tanks can have one, two or three fittings. One fitting is made on single-section GTZ tanks, and two and three on two-section tanks, the third fitting can be used to supply fluid to the cylinder of the hydraulic clutch drive.

Two types of plugs are used to seal the tank:

● Conventional with built-in valve(s);

● With valves and liquid level sensor.

Design and installation of the GTZ tank

Conventional plugs have valves to equalize the pressure in the reservoir (outside air intake) and release pressure when heated or there is too much liquid in the system. In the plugs of the second type, in addition to the valves, a float-type liquid level sensor is built-in, connected to the indicator on the dashboard. The sensor is a threshold sensor, it is triggered when the liquid level drops below a certain limit, closing the circuit of the corresponding warning lamp.

Installation of tanks can be performed in two ways:

● Directly on the GTZ body;

● Separate from GTZ.

In the first case, the tank with its fittings through sealing rubber bushings is installed in the holes in the upper part of the GTZ case, additional clamps or brackets can be used for reliable fixation.In the second case, the tank is installed in a convenient place in the engine compartment or in another area, and the connection to the GTZ is made using flexible hoses. The tank is attached to a metal bracket with clamps or screws, the hoses are crimped with clamps. A similar solution can be found on some domestic cars, including the VAZ-2121.

GTZ tank for placement separately from the cylinder

GTZ with tank installed

In any case, it selects a position of the reservoir in which the brake fluid can flow by gravity into the brake master cylinder, ensuring the normal operation of the entire system in various conditions.

How to choose and replace the brake master cylinder reservoir

GTZ tanks are simple and reliable, but they can fail due to exposure to aggressive environments, mechanical and thermal influences - any cracks, fractures of fittings or deterioration of the strength of the plug fixation can lead to deterioration of the brakes and to an emergency. Therefore, the tank should be regularly inspected (with scheduled maintenance of the brake system), and if malfunctions are detected, change the assembly.

For replacement, you should take the GTZ tank only of the type and model recommended by the vehicle manufacturer. For domestic cars, it is easier to find tanks, since many of them use unified parts, for foreign-made cars, you need to use tanks only in accordance with their catalog numbers. At the same time, it is recommended to purchase bushings, hoses (if any) and fasteners.

Replacement of the tank must be carried out in accordance with the repair instructions for this particular vehicle model. But in general, the order of work is as follows:

1.Remove the liquid from the tank (it is recommended to use a large syringe or bulb);

2.If there is a fitting for the clutch master cylinder, disconnect the hose from the tank and position it so that liquid does not flow out of it;

3.If there is a tank fastening, remove it (remove the screws, remove the clamp);

4.Dismantle the tank, if it is two-section, remove it from the holes by hand force, if it is single-section, remove it from the threaded fitting;

5.Inspect the bushings, if they are damaged or cracked, install new ones, after cleaning the place of their installation and the upper part of the cylinder body;

6.Install a new tank in reverse order.

Upon completion of the work, you should replenish the brake fluid supply and pump the system to remove air bubbles. After pumping, it may be necessary to replenish the liquid to the required level indicated on the tank. With the right choice of tank and its proper replacement, the car's brake system will work efficiently and reliably in any conditions.

Post time: Jul-11-2023