In cars with manual transmissions, the transfer of force from the lever to the shift mechanism is carried out by the gear shift drive. The shank plays an important role in the operation of the drive - read all about this part, its purpose, types, design, as well as the choice of a new shank and its replacement in the article.

What is a gearbox shank

The gearbox shank is an element of the gearbox shift drive with manual control (mechanical gearboxes); A part that directly connects the drive rod to the gear shift lever.

The gearbox shank has several functions:

- Connection of the drive rod and the remote gear shift mechanism;

- Compensation of longitudinal and transverse displacements of drive parts while the vehicle is moving;

- Drive adjustment.

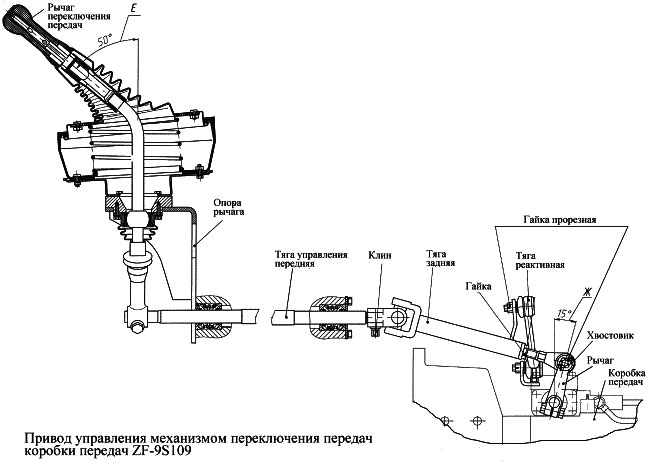

Gearbox shanks are used in gearshift drives based on rigid rods, in cable drives, the role of this part is played by other components (translators). Shanks of various types can be found in gearshift drives of trucks and cars, as well as in tractors and other equipment. The shank, being part of the gear shift drive, plays an important role in the control of the transmission. In the event of a breakdown, this part must be replaced, and for the correct choice and successful repair, you need to know about the existing types and features of shanks.

Types and design of gearbox shanks

The gearbox shanks used today can be divided into types according to the design and method of connection with the gear shift mechanism.

By design, shanks are of two main types:

• Threaded tip;

• Tubular traction.

The shank of the first type has a design similar to the steering tips - this is a short steel rod, on the one hand of which a thread is cut for mounting in the drive rod, and on the other hand there is a hinge for connecting to the lever of the switching mechanism on the gearbox.

The shank of the second type is a steel tubular rod, which on the one hand can be connected to the main rod, and on the other hand has a hinge for connection with the switching mechanism on the gearbox. This shank can be connected to the main rod using brackets or a clamp with a threaded clamp.

According to the method of connection with the gear shift mechanism, shanks are of two types:

• With rubber-metal hinge (silent block);

• With ball joint.

Tubular gearbox shank with ball joint and bracket for jet thrust

In the first case, a rubber-metal hinge is located at the end of the shank, and the connection to the lever of the switching mechanism on the gearbox is carried out using a bolt. In the second case, a maintenance-free ball joint is installed on the shank, the pin of which is connected to the lever of the switching mechanism on the gearbox. Ball joint shanks are more efficient, they better compensate for longitudinal and transverse displacements of drive parts while the car is moving (due to displacement of the gearbox, engine, cab, deformations of the frame or body, etc.) and fight vibrations. Shanks with silent blocks are simpler and cheaper, so they are also widely used.

Also, gearbox shanks can be divided into two groups according to the presence of additional connections:

• Without additional connections with drive parts, these are threaded tips;

• Connection to the jet thrust (rod) of the gear shift drive.

In the first case, the reaction rod is connected to the main rod of the drive. In the second case, a bracket is provided on the shank, with which the pin of the jet thrust ball joint is connected. The second end of the rod is pivotally connected to the gearbox housing or (less commonly) to the vehicle frame. The presence of jet thrust prevents spontaneous gear shifting while the vehicle is moving due to the displacement of the gearbox, cab, engine and other parts.

Gearshift drive with shank in the form of a threaded tip

As already mentioned, the gearbox shank occupies an intermediate position between the main drive rod, with which the gear lever in the cab is connected, and the shift mechanism lever mounted directly on the gearbox. Since the drive is subjected to vibrations and significant loads, its threaded connections provide protection against spontaneous unscrewing of nuts. The threaded tip, as a rule, has a locknut, and the clamping of the hinge nuts on the side of the gearbox can be carried out with a cotter pin (for which a core nut is used). This prevents excessive backlash and ensures reliable operation of the drive in all conditions.

Issues of selection and replacement of gearbox shanks

The gearbox shank is a reliable and durable part, but in some cases malfunctions may occur in it. The most common problem is the wear of the hinges (ball joint or silent block), which is manifested by an increase in backlash, an increase in the intensity of vibrations on the gear lever. In this case, the part must be replaced, since most often the hinges cannot be repaired. Deformations and breakdowns of shanks and their individual parts are also possible - a bracket for jet thrust, a clamp, etc. And in these cases, the part must be replaced.

When choosing a new shank, it is necessary to be guided by the catalog of parts of a particular car, since a different type of shank cannot be used in most cases. The replacement of the part and adjustment of the gear shift drive should be carried out in accordance with the recommendations for the repair and maintenance of the vehicle. If all the work is done correctly, the mechanism will work reliably, providing confident control of the transmission and the entire car.

Post time: Aug-18-2023