Almost all four-stroke piston internal combustion engines have a camshaft-based gas distribution mechanism. Everything about camshafts, their existing types, design and features of work, as well as the correct choice and replacement of shafts, read the proposed article.

The purpose of the camshaft and its place in the power unit

Camshaft (RV, camshaft) is a component of the gas distribution mechanism (timing) of piston four-stroke internal combustion engines that controls the gas exchange process; A metal shaft with molded cams of a special profile, which ensures the opening and closing of the valves in order to inlet a combustible mixture or air into the cylinder and release the exhaust gases in accordance with the movement of the pistons and the operation of all cylinders.

Timing is one of the main systems of the reciprocating internal combustion engine, thanks to it, the supply of air-fuel mixture (in carburetor engines) or air (in injectors and diesel engines) to the cylinders is ensured, and the exhaust gases are released from the cylinders only at strictly defined moments. Gas exchange is carried out by means of valves built into each cylinder, and their drive and synchronization of work with the crank mechanism and other systems of the power unit is carried out by one part - the camshaft.

The RV is entrusted with a number of key functions:

● Actuator (direct or indirect through intermediate parts) of intake and exhaust valves;

● Ensuring synchronous operation of the timing with other systems of the power unit;

● Ensuring the opening and closing of the intake and exhaust valves in accordance with the specified valve timing (for the intake and exhaust of gases at a certain angle of rotation of the crankshaft relative to TDC and the beginning / end of strokes);

● In some cases, the drive of various mechanisms and components, including those working synchronously with the timing (ignition breaker-distributor, oil pump, etc.).

The main role played by the RV is to control the operation of the timing valves in accordance with the design valve timing phases of this particular power unit. Thanks to the special design, the camshaft ensures the opening and closing of all valves only at the right time, sets the angles of their overlap at certain strokes, etc. A worn, deformed or damaged camshaft disrupts the functioning of the power unit or completely disables it, such a shaft requires immediate replacement. But before buying a new part, you should understand the existing types of RV, their structure and applicability.

Types, structure and characteristics of camshafts

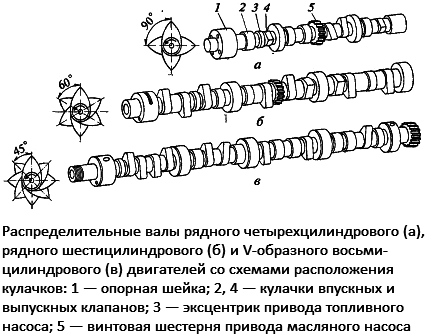

In general, the RV is made in the form of a metal shaft of small diameter, on which several elements are formed:

● Cams;

● Support necks;

● Gear and/or eccentric drive of various mechanisms;

● Sock for mounting the drive pulley/gear.

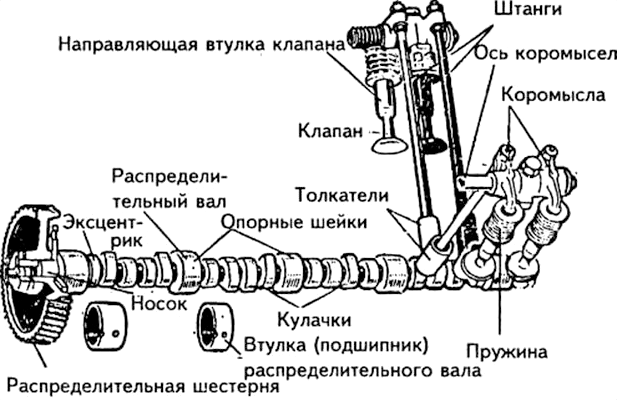

The main elements of the camshaft are cams, the number of which in the engine without a phase change mechanism corresponds to the total number of valves (both at the intake and at the exhaust). The cams have a complex drop-shaped profile, when the RV rotates, the cams run in and run off the pushers, thereby providing a valve drive. Due to the peculiarities of the cam profile, not only the opening and closing of the valves is achieved, but also maintaining them in the open state for a certain time, overlapping in accordance with the phases, etc.

The tops of all cams are shifted relative to each other, which ensures the sequential operation of all cylinders in accordance with the order determined for a particular power unit. In the RV for four-cylinder engines, the tops of the cams of one cylinder are shifted by 90 degrees, for six-cylinder engines - by 60 degrees, for eight-cylinder V-shaped engines - by 45 degrees, etc. However, you can often find exceptions due to the design features of the motor.

The RV is installed in the block or head of the engine by means of support journals in specially designed holes or beds. The RV rests on detachable (liners) or one-piece (bushings) rolling bearings made of special alloys with a low coefficient of friction. Holes are made in the bearings to supply engine oil to the journals from the general engine lubrication system. In the bearing of one of the journals (usually front or rear), a thrust ring or other locking device is made to prevent axial movements of the RV.

In any convenient place of the RV, a helical gear or an eccentric can be formed to drive various units. With the help of a gear, the drive of the oil pump or distributor is usually realized, and with the help of an eccentric, the drive of the oil pump is realized. On some types of RV, both of these elements are present, on modern motors, on the contrary, these elements are not present at all.

In front of the shaft there is a toe, on which a drive pulley or gear is mounted by means of a key and a bolt. A removable counterweight can also be located here, which provides balancing of the camshaft in the presence of a pump drive eccentric or other asymmetrical parts on it.

RVs are divided into several groups according to the method of installation and quantity in one motor, the type of drive, applicability in various types of timing and some design features.

According to the method of installation, camshafts are divided into two main groups:

● Installation directly in the engine block (motors with a lower shaft);

● Installation in the block head (motors with an overhead shaft).

Usually, there are no additional elements in the lower shafts, their lubrication is carried out due to oil mist in the crankcase and the supply of oil under pressure to the support journals through the bushings. In the upper shafts there is often a longitudinal channel and transverse drilling is performed in the support journals - this ensures that the journals are lubricated by applying oil under pressure.

Camshafts of various types of engines

The engine can have one or two RV, in the first case, one shaft provides a drive for all valves, in the second case, one shaft provides a drive only for the intake valves, the second for only exhaust valves. Accordingly, on the total RV, the number of cams corresponds to the number of all valves, and on each of the separate RVs, the number of cams is half the total number of valves.

The RV can be driven by a belt, chain or gear directly connected to the crankshaft gear. Today, the first two types of actuators are most often used, since the gear drive is less reliable and difficult to adjust (it requires significant disassembly of the unit for setting phases or for repair).

Finally, all RVs can be divided into two groups according to the type of gas distribution mechanism in which they can function:

● For engines with conventional timing;

● For units with timing with variable valve timing.

In the camshafts of the second type, there may be additional cams, shifted at a small angle relative to the main cam - with their help, the valves are driven when the phase changes. Also, these shafts can have special elements for turning, displacing the entire part along the axis, etc.

RVs of all types and designs are made of steel or cast iron, the surfaces of the cams of steel RVs additionally undergo heat treatment (quenching with high-frequency currents), the cams of cast iron RVs are bleached (bleaching by increasing the cooling rate of the casting) - this achieves an increase in the wear resistance of parts. The finished shafts are balanced to reduce runouts, and only then are installed on the engine or sent to retail chains.

How to choose and replace the camshaft correctly

The camshaft is subject to wear over time, chips and hardening form on its cams, and under certain conditions the part is partially or completely destroyed. In all these cases, the shaft should be replaced with a new one. This work requires significant disassembly of the engine and additional adjustment operations, so it is better to entrust it to a specialist or car service.

Camshaft and its place in the timing

For replacement, it is necessary to take the camshaft only of the type and model that was installed on the engine earlier. Often, for the purpose of tuning or improving the operation of the motor, shafts with a different profile and cam arrangement are used, but such a replacement should be done only after performing the necessary calculations. Also, along with the shaft, it is necessary to buy new bushings or liners, sometimes it is necessary to change the pulley, distributor drive gear and other parts. Work on replacing the shaft should be carried out only in accordance with the instructions for repairing the engine, after which the break-in is carried out.

With the right choice and replacement of the camshaft, the entire timing of the engine will work reliably and confidently, ensuring the functioning of the power unit in all modes.

Post time: Jul-13-2023