In the pneumatic system of a car or tractor, a certain amount of moisture (condensate) and oil always accumulates - these impurities are removed from the receivers through the condensate drain valves (valves). Read all about these cranes, their types and designs, as well as their correct selection and replacement, in the article.

What is a condensate drain valve?

Condensate drain valve (condensate drain valve, drain valve, drain valve) - a component of the brake system of vehicles with a pneumatic drive; A manually operated valve or valve designed to forcibly drain condensate and bleed air from receivers.

During the operation of the pneumatic system, condensate and oil droplets coming from the compressor accumulate in its components - receivers (air cylinders) and pipelines. Moisture condenses in the system due to compression with heating and subsequent cooling of the air, and oil penetrates from the lubrication system of the compressor The presence of water in the system leads to intense corrosion of its elements, and in winter it can disrupt the normal functioning of taps, valves and various devices. Therefore, the receivers provide special service devices - valves or taps for draining condensate (water) and oil.

With the help of condensate drain valves, several main tasks are solved:

● Forced drainage of condensate from air cylinders during daily maintenance or as needed;

● Removal of oil accumulated in the receivers;

● Forced venting of air from receivers to reduce pressure in the system (for example, for repairs and maintenance), to check the operation of the compressor and other equipment, and for other purposes.

The condensate drain valve ensures the normal operation of pneumatically operated brake systems, so the breakdown of this part should be eliminated as soon as possible. But before purchasing and installing a new crane, you should understand the existing types of these devices, their design and application features.

Types and design of condensate drain valves

Two types of devices are used to drain condensate, differing in the principle of operation and design:

● Valves;

● Valves with different types of shut-off element.

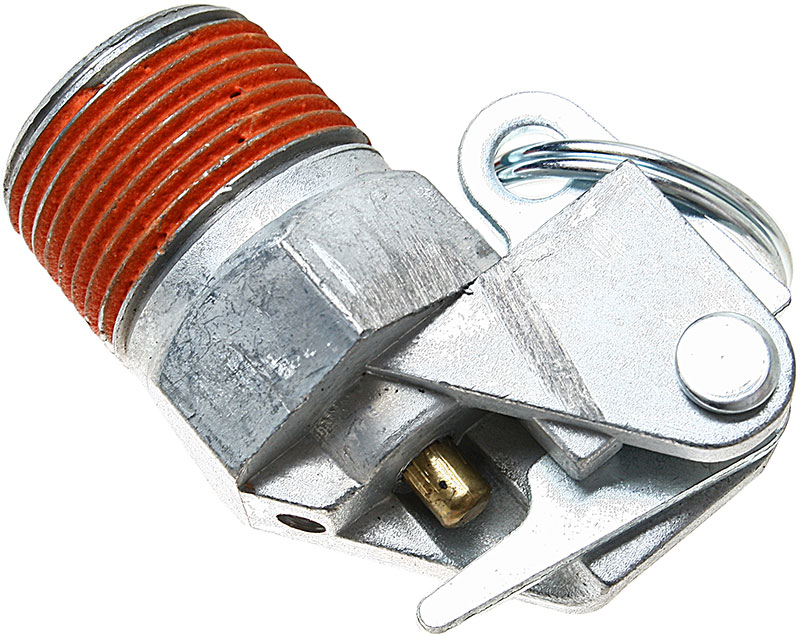

Valves are the simplest devices that can only be in the "Closed" and "Open" positions. Today, pressure valves with two types of actuators are used:

● With direct rod drive (with tilting rod);

● With lever rod drive (with push rod).

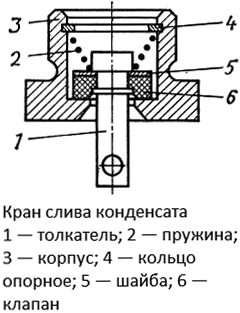

Condensate drain valves of the first type generally have a simple design. The basis of the device is a case in the form of a cork, threaded on its outer surface and a standard turnkey hexagon is provided. Inside the body there is a valve - an elastic round plate mounted on the rod (pusher), the pusher is passed through a hole in the front wall of the body, and the valve plate is pressed against the wall by a twisted conical spring (a metal ring or plate is provided for its stop). A transverse hole is drilled at the outer end of the stem for the installation of the ring for use as part of the remote condensate drainage system. The valve body is usually made of brass or bronze, but today there are also plastic products. The stem is usually steel, which ensures high strength of the product.

The design of the condensate drain valve (valve)

Condensate drain valve with lever actuator

Valves with a lever mechanism differ only in the presence of a short metal lever that ensures that the stem is pressed. This design is more convenient at high pressures, and it also provides a more confident opening and closing of the valve. Lever-driven devices are most often used on foreign heavy-duty trucks.

The condensate drain valve works as follows: under the action of the pressure inside the receiver and the spring force, the valve is closed, ensuring the tightness of the system; To drain the condensate or bleed air, it is necessary to move the stem sideways (but do not press it) - the valve will rise and air will be lowered through the resulting hole, which carries condensate and oil with it. For the convenience of shifting the stem, the hole in the front end of the valve is countersunk. For remote condensate drainage systems, a steel ring is installed on the rod, which is connected to the control cable - this cable is passed through the body or frame of the vehicle, its second end is connected to the handle in the cab. When this handle is pressed (or shifted), the cable pulls the valve stem, which ensures the drainage of condensate. Such a system is used on many domestic buses and trucks with a large number of receivers.

Condensate drain valves (or, as they are sometimes called, drain valves) are more complex devices, today they are used quite rarely (they can often be found on old domestic trucks). Structurally, it is a ball or cone valve, the shut-off element of which is connected to a rotary handle. The basis of the crane is a body, inside which a ball or cone with a hole is installed on its seats, and a turnkey thread and hexagon are made on the outer surface (not in all devices). The shut-off element of the valve is rigidly connected to the handle rod, which exits the housing through the seal. Valves are also most often made of brass and bronze, locking elements can be steel. The valve works as follows: in the closed position, the shut-off element is rotated in such a way that the hole in it is unscrewed and the channel of the crane body is blocked; When the handle is turned, the locking element also rotates, and air with condensate and oil escapes through the hole in it.

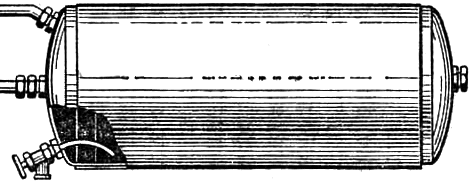

Most valves and valves have an M22x1.5 thread, the device is mounted in a boss with an internal thread welded at the lowest point of the air cylinder - on its lower surface (with a shift to one of the ends for ease of maintenance - this side of the receiver is directed to the outside of the car frame) or at the bottom point of one of the end walls. Valves are usually installed in a boss on the bottom surface, and drain valves can be located on the end walls - in this case they have a bend to direct the flow of air with condensate vertically downwards. Valves and cranes are equipped with most or all receivers with the pneumatic system of a vehicle, tractor or other equipment.

Issues of selection and replacement of the condensate drain valve

Over time, the parts of the valve and valve - the shut-off element and its seat, springs, etc. - wear out and deform, which leads to air leaks or disruption of the normal operation of the valve. Such a part can cause inefficient operation of the pneumatic system, so it must be replaced.

The selection of a new condensate drain valve is simple - all (or at least most of the parts used on popular truck models) on the market today are standardized, so you can take almost any of them for a car. At the same time, it is desirable to put the same valve on those receivers where the valve originally stood, and a crane on receivers with a crane. For vehicles with a remote condensate drainage system, a valve with a steel ring in the stem is needed, which is connected to the drive cable. The new part must have the same thread and working pressure, otherwise the crane will not fall into place or will not work properly.

Car receiver with condensate drain valve in the end wall

Additional (reinforced) polymer bushings, clamps and brackets can also be located on the cable sheath - these are the mounting elements necessary for the correct location of the cable and its fastening on the elements of the body or frame of the vehicle.

As a rule, the length and other characteristics of the cable are indicated on its label or in the relevant reference books - this information helps to choose a new cable when the old one wears out.

Replacement of the part must be carried out in accordance with the vehicle repair instructions. Usually, the work is reduced to unscrewing the crane with a key and installing a new part in its place, before starting work, it is necessary to release the pressure from the system, and the installation of a new crane must be carried out through the appropriate O-ring.

The operation of the condensate drain valve/valve is simple. If we are talking about a valve, then to drain the condensate, it is necessary to move the stem sideways (or press the lever of the valve with a lever drive) and wait for the intake of dry and clean air, after releasing the stem, the valve will close due to the force of the spring and air pressure. If there is a faucet on the receiver, then it is necessary to turn its handle to the "Open" position, and after removing moisture, turn the handle to the "Closed" position. Such maintenance should be carried out daily or as needed.

With the correct selection and replacement of the condensate drain valve, the pneumatic system of a car, tractor or other equipment will be protected from moisture and oil during the entire service life.

Post time: Jul-26-2023