In cars with a manual transmission, there is a clutch, in which an important place is occupied by a small part - the fork. Learn about what a clutch fork is, what types it is, how it works and how it works, as well as the correct selection and replacement of forks in clutches - find out from this article.

What is a clutch fork?

Clutch fork (clutch release fork) - a part of the clutch drive of vehicles equipped with a manual transmission; A part in the form of a fork (lever with two legs) that ensures the transfer of force from the cable or slave cylinder to the clutch / release bearing when the clutch is disengaged (by pressing the corresponding pedal).

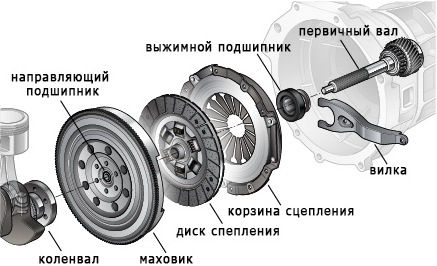

In vehicles with a manual transmission, a clutch is provided - a unit that ensures a break in the flow of torque coming from the engine to the gearbox at the time of gear shifting. The clutch has a remote drive, which includes a pedal, rods or cables, in some cases - a power steering (built on the basis of the main and working cylinders of the clutch, GCS and RCS) and a clutch with a release bearing. The transmission of force from the cable, rod or RCS to the clutch at the time of gear change is carried out by a special part - the clutch fork.

The clutch release fork has one main function - it acts as a lever that converts the force from the rod, cable or RCS, and brings the clutch (release bearing) to the clutch basket (its diaphragm spring or levers). Also, this part solves a number of auxiliary tasks: preventing clutch distortions, compensating or adjusting backlash in the clutch drive, and in some types of clutches - not only the supply, but also the removal of the clutch from the basket. The fork is extremely important for the normal functioning of the clutch, so in case of any breakdown, it must be changed to a new one - in order to make the right replacement, you need to understand the types, designs and features of these parts.

Types and design of clutch forks

Today, there is a wide variety of clutch fork designs, but they are all divided into two types according to the principle of operation:

● Lever;

● Rotary.

Clutch lever forks are generally a lever at one end of which there are two legs for support in the release bearing, and at the opposite end there is a hole or special fasteners for connection to the drive. The fork has a support inside the clutch housing, thanks to which the operation of this unit as a lever is ensured. According to the type and location of the support, there are:

● Ball separate - the support is made in the form of a short rod with a spherical or hemispherical tip on which the fork is located. A recess for support is provided on the fork, and fixation on the ball tip is carried out using springy brackets;

● Axial integrated - the support is made in the form of a plate, which is connected to the plug by an axis. The connection of the parts is carried out by means of an axis threaded and fixed in the holes drilled in the eye of the support and the legs of the fork;

● Axial separate - the support is made in the form of two removable struts or eyelets directly in the clutch housing, the fork rests on the struts by means of an integrated or removable axis.

Ball bearings usually have forks made by stamping from sheet blanks, these parts are most widely used in passenger cars and commercial trucks today. To increase the strength of the fork, stiffeners are made, and reinforcing pads and other elements may also be present on the parts.

Axial supports of both types are most often provided for forks made by volumetric stamping from hot blanks, these parts, due to their increased strength, are most widely used in the transmission of trucks. The paws of such parts can have a different shape - round or semicircular, oval, etc. Also, reinforcing elements can be located on the paws - steel crackers or rollers that are in direct contact with the clutch.

Clutch swivel forks are generally made in the form of a shaft on which there is a fork with two legs and a lever for connecting to the clutch release drive. By design, such parts are of two types:

● Non-separable - the fork is made by welding two legs and a swing lever to the shaft;

● Collapsible - the unit consists of a steel shaft on which a removable fork and a swing arm are fixed.

Cluth

linkage fork Swivel clutch fork manufactured by volumetric stamping

technology Non-separable clutch swivel fork

Non-separable forks are most often used on passenger cars, they are made of steel sheet blanks (stamped from a sheet several mm thick) welded at opposite ends of the shaft. Workpieces can be thermally hardened.

Collapsible forks are most widely used in freight transport, the basis of the part is a steel shaft, at one end of which a fork is mounted (made, as a rule, by the method of volumetric stamping), and at the other - a swing arm. Usually, the fork has a split clamp with a bolt hole, this design allows it to be mounted on the shaft in any position and, if necessary, adjusted. The swing arm is attached to the shaft with a slot, which prevents the parts from turning during operation. The forks may have additional hardening elements on the paws in the form of rollers or breadcrumbs, and the fork paws themselves are thermally hardened.

All forks, regardless of type and design, are mounted inside the clutch housing, on the side or bottom of the clutch/release bearing. The lever forks are located on a support (or two supports) fixed with a threaded connection. Usually, the back of the fork extends beyond the clutch housing, to prevent dirt and water from penetrating into the unit, a protective cover made of rubber (corrugation) or non-woven materials (tarpaulin or its more modern analogues) is provided. The cover is fastened with special clips.

Swivel forks are installed in the holes in the clutch housing, which include the ends of the shaft. In this case, the swing arm can be located both inside the crankcase and outside it. In the first case, only the cable or rod connected to the lever comes out of the crater, in the second case, part of the shaft comes out of the crankcase. Swivel forks can be installed through bushings (plain bearings) or rolling bearings, oil seals or other seals are used to protect the clutch housing from water and dirt.

Clutch fork selection and replacement issues

During the operation of the vehicle, the clutch fork is subjected to significant mechanical loads, which can lead to their malfunction. Most often, forks are deformed (bent), cracks and fractures appear in them, and quite often there is a complete destruction of the part. With deformations and cracks, the reaction of the clutch to pedal pressure worsens - to release the clutch, the pedal has to be squeezed deeper and deeper (which occurs due to increasing deformation or a growing crack), and at some point the transmission completely stops responding to the pedal. When the fork is destroyed, the clutch pedal immediately weakens, and it becomes impossible to change gears. In all these cases, the plug must be replaced with a new one.

Stamped fork clutch

Only the part that fits the clutch of this particular car should be taken for replacement. If the car is under warranty, then the plug must have a certain catalog number (so as not to lose the warranty), and for older cars, you can use "non-native" parts or suitable analogues. The main thing is that the new fork matches the old one in all sizes, the type of connection to the support (if it is a lever fork), the diameter of the shaft (if it is a swivel fork), the type of connection to the actuator, etc.

Replacement of the clutch fork must be carried out in accordance with the vehicle repair instructions. As a rule, this work requires dismantling the gearbox, although in some cars the replacement of the part can be performed through special hatches in the clutch housing. When replacing the fork, it is necessary to use related parts - fasteners, supports, crackers or rollers, etc. If these parts are not included, then they must be purchased separately. After replacing the fork, the clutch must be adjusted according to the appropriate instructions. With the right selection of spare parts and proper repairs, the car's clutch will begin to function again, ensuring handling and safety.

Post time: Jul-14-2023