In a friction-type clutch, the interruption of the torque flow when shifting gears is realized by separating the pressure and driven discs. The pressure plate is retracted by means of a clutch release clutch. Read all about this part, its types, design and the right choice in the article.

What is a clutch?

Clutch (clutch release clutch, push clutch) - friction clutch assembly in a transmission with manual control; A component of the clutch drive that ensures that it is disengaged when shifting gears.

The clutch release clutch performs two functions:

• Fastening and correct positioning of the clutch release bearing (release bearing);

• Transmission of force from the clutch drive (from the clutch release fork) to the bearing and then to the diaphragm spring blades / levers;

• Protection of the release bearing from mechanical stress and wear (prevents breakage and wear of the bearing, possible with direct contact with the fork).

Please note: the term "clutch" is also used in relation to a larger unit - an automotive clutch of various types (as a rule, to a friction single and double plate). This article discusses clutches.

Types and design of clutches

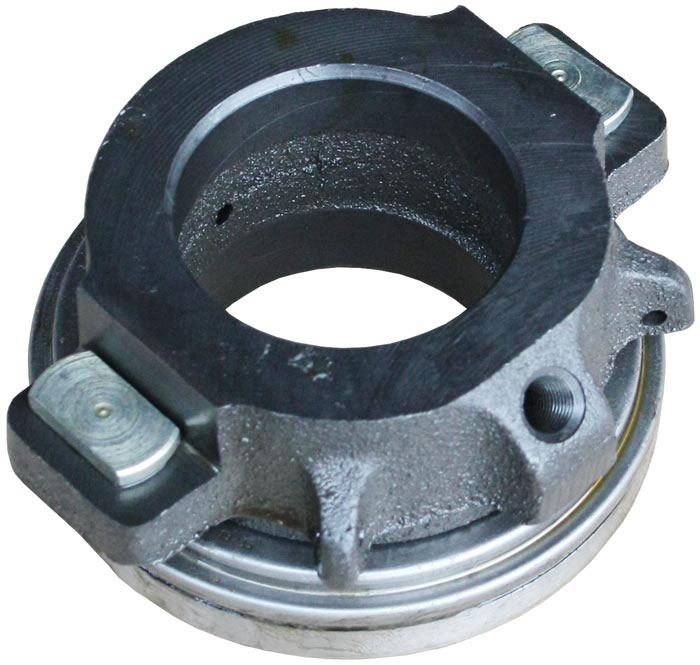

All clutches have a fundamentally identical device, differing in details. In general, this is a solid cylindrical part, which can be conditionally divided into several parts:

• Mounting hole - a hole along the axis of the clutch for its landing on the input shaft of the gearbox;

• Thrust surfaces - rectangular thrust pads or pins (two pieces) for connection to the clutch release fork;

• Clutch release bearing seat - extended part in the form of a cup or tubular part for mounting the release bearing.

The clutch can be made of cast iron and steel, today plastic parts are also increasingly used. The couplings differ in the design of the thrust surfaces under the fork (respectively, and the design of compatible clutch release forks) and the method of mounting the release bearing.

According to the design of the forks and thrust surfaces for them, the clutches for disengaging the clutch are:

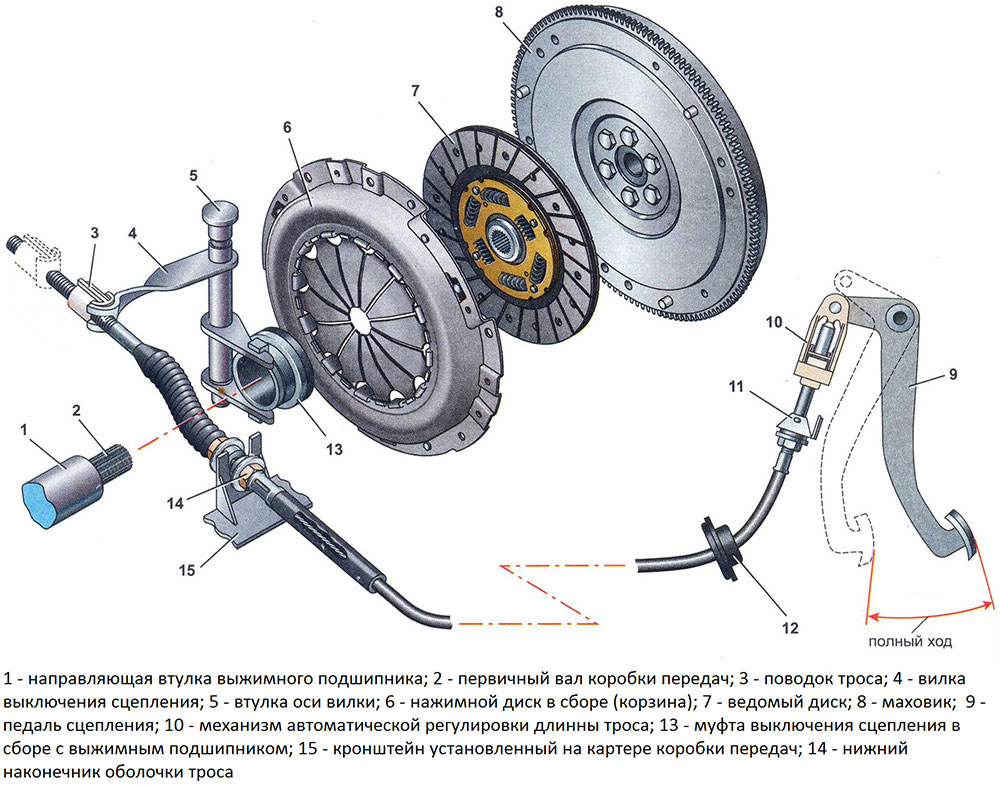

The overall design of the friction clutch and the place of the clutch release clutch in it

With flat pads without fixing the fork;

• With cylindrical pins;

• With various systems for articulating the coupling with the fork (by means of bolts or cotter pins).

As a rule, clutches with flat pads do not have a connection to the clutch release fork - it is supplied to the clutch only at the time of gear shifting, the reverse return of the clutch in this case is carried out due to the elasticity of the clutch basket springs. Couplings with pins or articulation are permanently connected to the fork, so they are brought to the clutch basket at the moment of gear change, and then forcibly retracted from it. To protect the plug contact points from intense wear, contact pads made of harder materials can be additionally used.

According to the type of mounting of the release bearing, couplings are:

• With internal installation of the bearing - a mounting hole is made on the coupling in the form of a cup into which the bearing is inserted;

• With external installation of the bearing - a tubular part is made on the coupling, on which the bearing is pressed.

Couplings can use thrust or angular contact bearings of various designs. Self-aligning bearings are widely used, which are able to work better under conditions of constantly changing axial loads.

The principle of operation and the place of the clutch in the transmission of the car

The clutch release clutch is part of the friction clutch, it is located on the input shaft of the gearbox with the possibility of axial movement along it. On the installation side of the release bearing, the clutch is adjacent to the diaphragm spring petals or clutch pressure plate levers. The clutch is connected to the clutch release fork and can use it to make axial movements along the input shaft of the gearbox.

If it is necessary to change gear, the driver presses the clutch pedal, with the help of the drive, the pedal acts on the fork - it shifts towards the clutch basket and pushes the clutch connected to it. The clutch, together with the bearing, fits the diaphragm blades or levers and pushes them - this leads to the removal of the pressure plate from the slave and the flow of torque from the engine to the gearbox is interrupted, you can safely shift gears. After engaging the desired gear, the driver releases the clutch pedal, the fork returns to its original position under the influence of the spring, retracting or releasing the clutch. The springs of the clutch basket are released, the pressure plate is pressed again in the slave - the flow of torque from the engine to the gearbox is restored.

Depending on the design, when the clutch is disengaged, the clutch with the bearing can either be completely removed from the clutch basket or have constant contact with the diaphragm spring blades/levers. However, in both cases, the clutch is in a free position (without clamping) and does not affect the operation of the clutch.

Clutch selection and replacement

The clutch operates under changing loads, so it wears out and becomes damaged over time. Release bearings are even more at risk of breakdowns. In the event of malfunctions, these parts are not repaired, but completely replaced. Signs of clutch malfunctions are problems with gear shifting - a change in the stroke of the clutch pedal, a decrease or increase in the resistance of the pedal to pressure, insufficient clutch release, the appearance of extraneous sounds when shifting gears, etc.

When choosing a new clutch, you need to focus on the size and configuration of the old one. It is best to buy a coupling of the same type and catalog number as the old one. However, in some cases, it is possible to use analogues that are suitable in size, type and location of the thrust pads for the fork, the bearing seat and the seat size for the input shaft of the gearbox. When installing a clutch with different dimensions and configurations, the clutch will not work correctly, or completely cease to perform its functions. With the right choice, the clutch will be released quickly and reliably, providing easy and safe gear changes.

Post time: Aug-21-2023