In cars with a cabover cab, an important auxiliary system is provided - a rollover mechanism with a hydraulic cylinder as a power element. Read all about the cylinders of the cab tipping mechanism, their existing types and designs, as well as their correct selection and replacement - read in this article.

What is a cab tipping mechanism cylinder?

The cylinder of the cab tipping mechanism (IOC cylinder, IOC hydraulic cylinder) is the actuator of the truck cab tipping mechanism with a cabover layout; Double-acting hydraulic cylinder for raising and lowering the cab.

The MOQ cylinder has several functions:

- Lifting the cab for maintenance or repair of the engine and other systems;

- Assisting the balancing mechanism in supporting the cab in an overturned position;

- Smooth lowering of the cab without jolts and jerks.

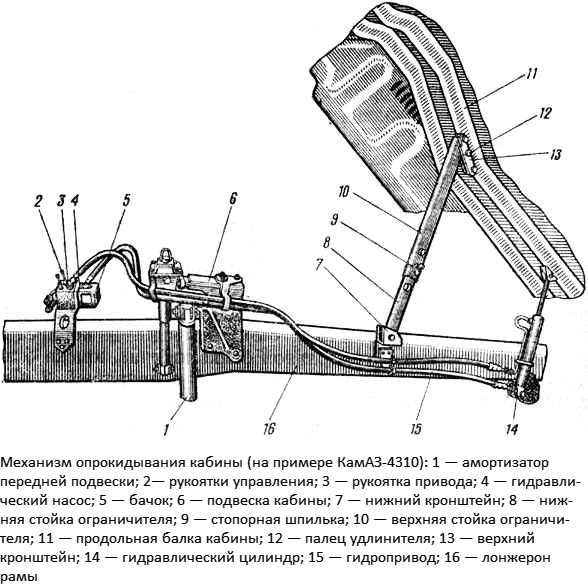

This hydraulic cylinder is part of the cab tipping mechanism (the system in some cars is combined with the spare wheel lifting mechanism), which consists of a manual oil pump, two pipelines, a reservoir for the working fluid and, in fact, the MOK cylinder. This mechanism works autonomously from the engine and other units of the car, it is mounted under the cab on the frame spar. The cylinder greatly facilitates and speeds up the maintenance of the car, ensuring safety requirements, so if it breaks down, repair or replacement should be performed as soon as possible. To choose the right hydraulic cylinder, you need to understand its design, operation and some features.

The design and principle of operation of the cylinder of the cab tipping mechanism

Cab tipping mechanism

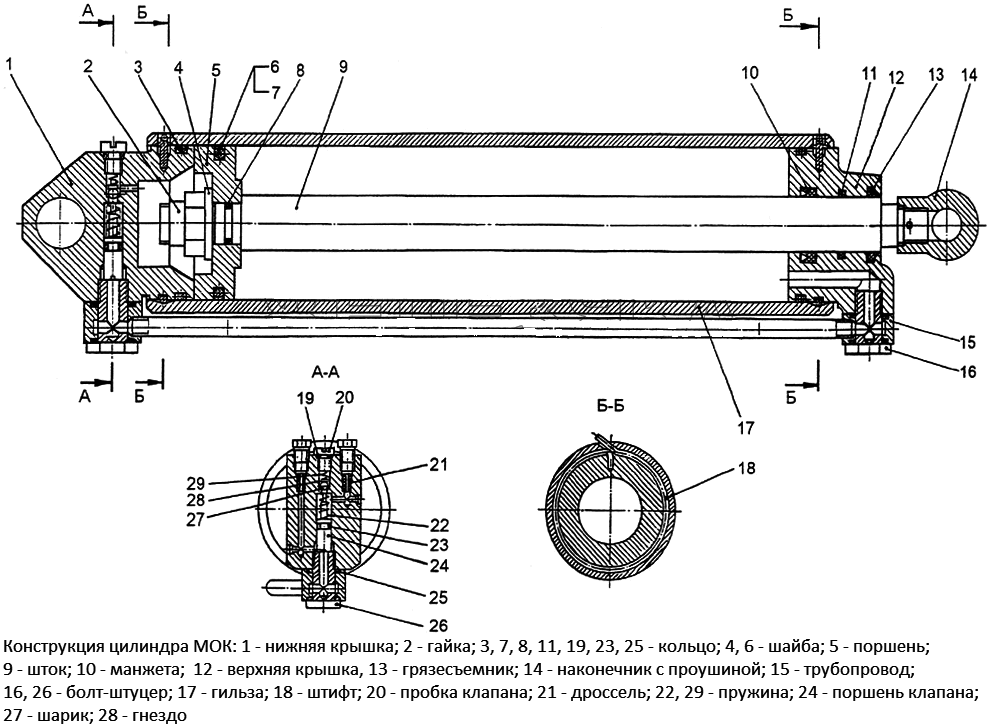

Currently, all cabover vehicles use double-acting IOC hydraulic cylinders with a built-in hydraulic throttling mechanism. The basis of the design of this device is a steel cylinder, closed at both ends with covers. On the cover covering the lower end of the cylinder, there is an eye for hinged mounting on the spar of the car frame. Inside the cylinder there is a piston with O-rings, the piston is connected to a steel rod that passes through the top cover (the seal is provided by a cuff) and ends with an eye for a hinge connection with a longitudinal beam or other power element of the cab.

In the covers of the MOK hydraulic cylinder there are fittings (or bolts-fittings) for connecting pipelines. In the top cover (on the side of the rod outlet), the fitting immediately passes into the channel through which the working fluid is supplied and discharged from the cylinder. In the bottom cover (on the side of installation on the frame) there is a throttle (throttle assembly) and / or a check valve, which limit the flow rate of the working fluid from the cylinder when the cab is lowered. The throttle is a narrowing of the channel carved into the cover, the passage of which can be constant or changed by an adjusting screw. A check valve (aka hydraulic lock) prevents the leakage of working fluid from the cylinder cavity when the cabin is raised.

The principle of operation of the MOK hydraulic cylinder is simple. If it is necessary to raise the cabin, the pump is rotated and the oil flows through the pipeline to the lower cover of the cylinder, the liquid passes through the channels into the cylinder and pushes the piston - under the action of the pressure created by the liquid, the piston moves and pushes the cabin through the rod, ensuring its overturning. If it is necessary to return the cab to its original position, oil is supplied to the upper cover of the cylinder, through which it enters the cylinder and pushes the piston - under the action of the created force, the piston moves down and lowers the cab. However, there is a throttle in the lower cylinder cover, which prevents the oil from flowing out of the cavity quickly - this creates a force that limits the speed of lowering the cabin, which prevents shocks and shocks.

The speed of lifting and lowering the cab is regulated by a throttle and a check valve, for which appropriate screws are provided on the top cover of the IOC cylinder (with a head for a slot or with a hexagon for an open-end wrench).

The design of the cylinder of the cab tipping mechanism

Cylinders can be divided into two groups according to the method of supplying the working fluid:

- With the connection of the lines directly to the top and bottom cover;

- With the connection of the lines to one cover (usually to the bottom) with the supply of oil to the second cover by a built-in metal tube.

The IOC cylinders of the first type are most simply arranged - on both covers there are fittings to which pipelines (hoses) from the MOC pump are connected. Hydraulic cylinders of the second type are more complicated, both fittings are located on the bottom cover, but one fitting is connected to a steel tube through which oil flows to the top cover. Devices of the second type make it possible to reduce the length of the oil lines and increase their reliability, since they are in the same plane and deform synchronously when lifting / lowering the cabin.

Modern MOK cylinders usually have small dimensions (length in the range of 200-320 mm with a diameter of 20-50 mm) and are designed for an oil pressure of 20-25 MPa. Devices of the described design are used both on domestic trucks (KAMAZ, MAZ, Ural) and on foreign-made vehicles (Scania, IVECO and others).

How to choose and replace the cylinder of the cab tipping mechanism

During the operation of the cabin tipping mechanism, the parts of its hydraulic cylinder are subjected to intense wear, and various kinds of breakdowns can also occur (deformation of the rod and cylinder, cracks in the cylinder, destruction of the eyelets, and others). In case of wear or malfunctions, the cylinder should be repaired or replaced in the assembly (which today is easier and cheaper). To replace, you should choose an IOC cylinder of the same type and model that was on the car earlier - this is the only way to guarantee that the entire mechanism will function correctly. This is especially true for new trucks, which are still covered by the warranty.

In some cases, it is possible to install "non-native" cylinders, but several parameters should be taken into account here:

● Operating pressure - it should be the same as that of the old cylinder;

● Installation dimensions and overall dimensions of the cylinder;

● Location and type of fittings - they should be located in the same place where the fittings were on the old cylinder, and have the same connecting dimensions.

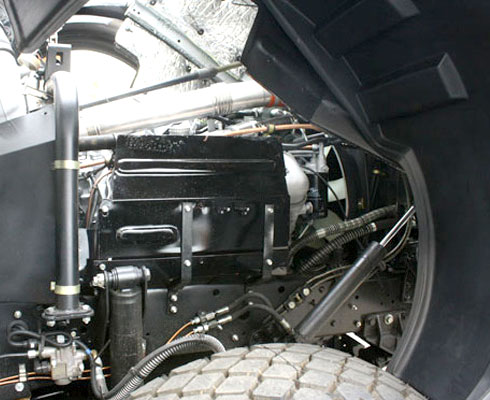

Location of the cwlinder and other parts of the cabtipping mechanism and' spare wheel lift

A cylinder with a different working pressure will not work correctly - either too slowly, or will not be able to provide a smooth lifting and lowering of the cab. If the new cylinder has fittings of other sizes, then the piping tips should also be replaced. And it will not be possible to install a cylinder of other sizes without altering the fasteners on the cab or frame, so the new unit must have the same length as the old one.

Replacement of the MOK cylinder should be carried out in accordance with the requirements of the repair manual and maintenance of this particular vehicle. Regardless of the order of work, first of all it is necessary to raise the cabin and ensure its fixation, its reliable fixation with the help of appropriate devices, as well as drain the working fluid from the system. After installing a new cylinder, you need to pour oil into the tank and pump the system (lower and raise the cab several times). In addition, it may be necessary to adjust the throttle (if this is provided for by the design of the hydraulic cylinder) - it should also be carried out in accordance with the instructions and taking into account the weight and characteristics of the cab.

To extend the service life of the MOK hydraulic cylinder and the entire mechanism, routine maintenance should be performed. Periodically, it is necessary to check the condition of the cylinder for leaks through oil seals, fittings and other parts, as well as for deformations and damage. You also need to monitor the level of the working fluid, if necessary, replenish it.

With the correct selection and replacement of the cylinder, the cab tipping mechanism will work quickly and reliably, ensuring ease of work and safety.

Post time: Jul-26-2023