Trucks and various heavy equipment use pneumatically operated braking systems, which are controlled by a brake valve. Read all about brake valves, their types, design and operation, as well as the correct choice and replacement of this unit in this article.

What is a brake valve?

Brake valve - the control element of the brake system of vehicles with a pneumatic drive; pneumatic valve driven by the brake pedal, which provides compressed air to the actuators (brake chambers) and other parts of the system during braking.

On trucks and other wheeled vehicles, pneumatically driven braking systems are most widely used, which are superior in efficiency and reliability to hydraulic systems. The control of the units of the system is carried out by special devices - valves and valves. One of the key roles in the pneumatic system is played by the brake valve, through which the wheel brakes are controlled.

The brake valve performs several functions:

● Ensuring the supply of compressed air to the brake chambers when it is necessary to perform braking;

● Providing a "brake pedal feeling" (a proportional relationship between the degree of braking of the car and the force on the pedal, which allows the driver to correctly assess the braking process and adjust this process);

● Two-section valves - ensuring the normal operation of one circuit in case of air leakage in another.

It is with the help of the brake valve that the brake system is controlled in all driving modes, so this unit is extremely important for the normal operation of the car. A faulty crane must be repaired or replaced, and for its correct choice it is necessary to understand the existing types, design and principle of operation of these devices.

Types, design and principle of operation of the brake valve

Brake valves used on vehicles are divided into two large groups according to the number of control sections:

- Single-section;

- Two-section.

Brake valve with pedal

Single-section cranes are installed on vehicles that are not operated with trailers equipped with air brakes. That is, this crane provides control only of the braking system of the car. Two-section cranes are used on vehicles that are operated with trailers / semi-trailers with an air brake system. Such a crane provides control of the brakes of the tractor and trailer from one pedal.

In turn, two-section cranes are divided into two types according to the location and method of controlling the sections:

● With lever control of each section - the drive is carried out using two hinged levers that have a single drive with a thrust from the brake pedal, in this device the sections are autonomous (not connected to each other);

● With a common rod for two sections - the drive of both sections is carried out by one rod, which is driven by a brake pedal, in this device one section can control the operation of the second.

The design and principle of operation of all valves are fundamentally the same, and the differences lie in the details described below.

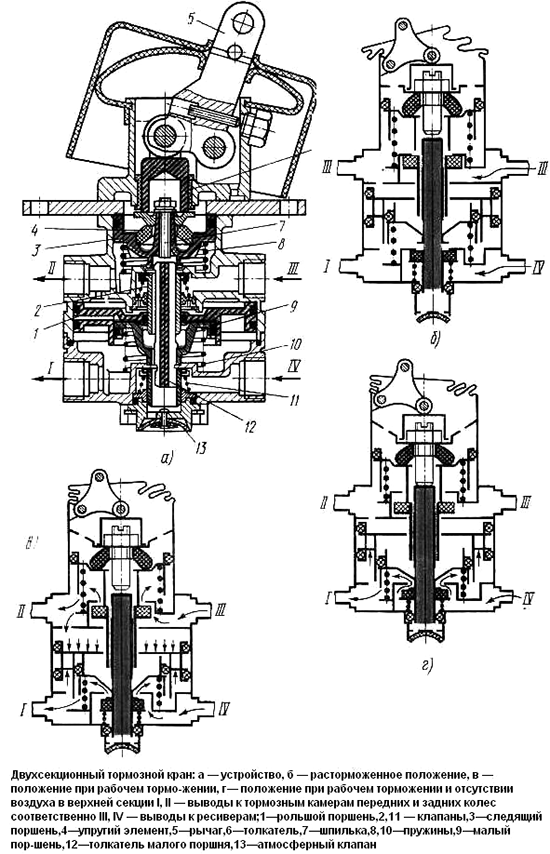

The crane section consists of several main components: the actuator, the tracking device, the intake and exhaust valves. All parts are placed in a common case, divided into two parts: in one part, communicating with the atmosphere, there is a drive and a tracking device; In the second part, connected by fittings to the receiver (receivers) and the brake chamber line, the intake and exhaust valves installed on the same rod are located. Parts of the body are separated by an elastic (rubber or rubberized) diaphragm, which is part of the tracking device. The actuator is a system of levers or a push lever that is connected to the brake pedal by a rod.

The tracking device is directly connected to the valve drive and the brake pedal, it consists of a rod and a spring (or a piston of a certain configuration), the end of the rod is located above the movable seat of the exhaust valve - a tube installed in the glass, which, in turn, rests against the diaphragm. There is a hole in the glass that provides communication between the second half of the body and the atmosphere. The intake and exhaust valves are made in the form of rubber cones or rings resting against their seats.

The brake valve works quite simply. When the pedal is released, the valves are arranged in such a way that the receiver line is blocked, and the brake chamber line communicates with the atmosphere - in this position the brake system is inactive. When the brake pedal is pressed, the tracking device ensures that the exhaust valve closes and the intake valve opens at the same time, while the valve cavity with the valves is disconnected from the atmosphere. In this position, compressed air from the receivers flows through the valves to the brake chambers - braking is performed. If the driver stops the pedal in any position, the pressure in the crane body, which is disconnected from the atmosphere, increases rapidly, the spring of the tracking device is compressed, the exhaust valve seat rises, which leads to the closure of the intake valve - the air from the receivers ceases to flow to the brake chambers. However, the exhaust valve does not open, so the pressure in the brake chamber line does not decrease, due to which braking is performed with one or another force. With further pressing of the pedal, the valves open again and air enters the chambers - braking is more intensive. This ensures the proportionality of the effort applied to the pedal and the intensity of braking, and, as a result, creates a "pedal feeling".

Design and operation of a two-section KAMAZ crane

When the pedal is released, the tracking device is removed from the valves, as a result of which the intake valve closes under the action of the spring, and the exhaust valve opens - compressed air from the brake chamber line goes into the atmosphere, disinhibition occurs. When you press the pedal again, all processes are repeated.

There are other designs of brake valves, including only one valve that replaces the intake and exhaust valves, but the principle of operation of such devices is similar to that described above. In some two-section cranes, one section (upper) can serve as a tracking device for the lower section, such devices have additional mechanisms to ensure the operation of the lower section in the absence of pressure in the upper section.

Brake valves, regardless of design and applicability, can have a number of auxiliary elements:

● Pneumatic brake light switch is an electro-pneumatic switching device that communicates with the valve cavity, which, when the pressure rises (that is, when braking) turns on the brake light of the car;

● Muffler ("fungus") is a device that reduces the noise level of air released into the atmosphere when the car is released;

● Manual drive - levers or rods by means of which you can manually brake / brake the car in emergency situations or for repairs.

Also on the crane body there are threaded leads for connecting pipelines from receivers and to the lines of brake chambers, brackets or tides with mounting holes and other elements.

Valves can be mounted in a convenient place next to other elements of the pneumatic system, or directly under the brake pedal. In the first case, a system of rods and levers is provided to transmit force to the crane, in the second case, the pedal can be located next to or directly on the crane and have a drive of minimum length.

Issues of selection, repair and replacement of brake valves

The brake valve is one of the most important controls of the brake system, so it needs regular maintenance, and if there is a malfunction, it must be repaired or replaced as soon as possible.

Only the type and model of the crane that was installed on the car earlier should be taken for replacement, if necessary, analogues with suitable characteristics (working pressure and performance), installation dimensions and drive type can be used. Installation of a new crane must be carried out in accordance with the instructions for the repair of the vehicle, the necessary fasteners, sealing elements and lubricants should be used during installation.

The crane is subjected to regular maintenance in accordance with the instructions of the car manufacturer. Each TO-2 is carried out by a visual inspection of the unit and checking its tightness (the search for leaks is carried out using special tools or soap emulsion and by ear), as well as lubrication of rubbing parts. Every 50-70 thousand mileage, the crane is dismantled and completely disassembled, washed and subjected to troubleshooting, worn or faulty parts are replaced with new ones, during subsequent assembly, lubricant and sealing elements are updated. In this case, it may be necessary to adjust the valve stroke and valve actuator. These works should be carried out by a qualified specialist.

With the right choice and replacement, as well as with regular maintenance, the brake valve will work reliably, ensuring effective control of the vehicle's braking system in all driving modes.

Post time: Jul-14-2023